-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Some New Goodies

- Thread starter thestelster

- Start date

-3" precision sine vise

-magnetic v-block and parallels

-Dial Indicator (to be affixed to the lathe).

Ordered from KBC yesterday, received today.

I'm finding the lines of the indicator between the numbers are too long.

What did the shipping come to?

Shipping: zero, but including several other bits and pieces, total came to around $600.00What did the shipping come to?

Permanent magnets. Therefore you have to use them with a magnetic chuck. I just tested them now they work, but not nearly as much holding power compared to just the mag chuck. But light passes should be fine, or if I block up the part being ground.I've wondered about those magnetic V-blocks. Do they have an on/off like maybe flush or recessed hex key, or are they permanent magnetic?

Yes.Do you mean the vee blocks become magnetically energized (only) when the mag base is 'on', otherwise they are basically non-magnetic just sitting by themselves?

Tom Kitta

Ultra Member

I've wondered about those magnetic V-blocks. Do they have an on/off like maybe flush or recessed hex key, or are they permanent magnetic?

They are transfer blocks. I got them as well. Used with magnetic chuck.

So doing some preliminary tests, the sine vice seems pretty accurate and square. Only real annoyance is that the spacing between the cylinders is 4.134" (105mm), so Ibetter write this down to make the angle calculations.

The magnetic 1-2-4 blocks are not parallel or square. By .003" from one end to the other. The other is a little better, but not by much. So I will surface grind them together to get a matched pair.

The magnetic 1-2-4 blocks are not parallel or square. By .003" from one end to the other. The other is a little better, but not by much. So I will surface grind them together to get a matched pair.

Chip Maker

Super User

That center distance seems really odd to me. Mine is 100 mm. Most common are 5" or 10" for Imperial or 100 mm. for metric.

Tom Kitta

Ultra Member

So doing some preliminary tests, the sine vice seems pretty accurate and square. Only real annoyance is that the spacing between the cylinders is 4.134" (105mm), so Ibetter write this down to make the angle calculations.

The magnetic 1-2-4 blocks are not parallel or square. By .003" from one end to the other. The other is a little better, but not by much. So I will surface grind them together to get a matched pair.

Yeah, cheap stuff from China. Mine were used but are also not close - have to grind them one day to make them all flat and square as matching pair. Through they no longer will be 1" or 2" or 3".

Make sure you grind them square - or you may end up with parallelogram.

Yeah I have had some house brand KBC & Travers stuff that is no different than generic Chinese/Indian stuff off Ali, Ebay, whatever. It's kind of frustrating when you have to see firsthand what you get. A name is basically meaningless. In my case the (smaller grinding style) vice was nice & square but the tightening screw assembly was hopelessly useless. Not only bad machining but ill fitting design. So strange where they decide to cut corners. I made a new one. You will have to decide for yourself but FWIW I've returned items to KBC (Delta) saying 'did not meet expectations'. I believe the policy is call them first & pay the return ticket home at your expense, but that have pretty good about it.

Now the question is, was 105mm exactly 105mm by intent or supposed to be 100mm? Seems odd

Now the question is, was 105mm exactly 105mm by intent or supposed to be 100mm? Seems odd

I just surface ground the pair of blocks, just on two large surfaces. They are now within 0.0002". I'll do the other sides tomorrow. 1 issue during the grinding was that the wheel started to get pieces of aluminium embedded in it, and I had to dress it a couple times.

As to the sine vise, I checked several times with micrometer and calipers, and agreed each time. Even with a ruler it measured 105mm. It doesn't really matter as long as I use that measurement in the calculations, all is good. (Though multiplying by five is pretty easy to remember as opposed to 4.134")

As to the sine vise, I checked several times with micrometer and calipers, and agreed each time. Even with a ruler it measured 105mm. It doesn't really matter as long as I use that measurement in the calculations, all is good. (Though multiplying by five is pretty easy to remember as opposed to 4.134")

Chip Maker

Super User

Try putting a light layer of oil on the blocks before grinding them. It will help reduce the aluminum embedding.I just surface ground the pair of blocks, just on two large surfaces. They are now within 0.0002". I'll do the other sides tomorrow. 1 issue during the grinding was that the wheel started to get pieces of aluminium embedded in it, and I had to dress it a couple times.

As to the sine vise, I checked several times with micrometer and calipers, and agreed each time. Even with a ruler it measured 105mm. It doesn't really matter as long as I use that measurement in the calculations, all is good. (Though multiplying by five is pretty easy to remember as opposed to 4.134")

Chip Maker

Super User

I took a large magnetic sine plate apart once in a shop I worked at. The sine plate was used on a wet grinder and it was rusting between the internal plates and getting really stiff to turn the chuck on. Upon disassembly I couldn't get one of the screws loose which held the rollers. When I took the screw off at the other end of the roller, the roller came off. It turns out that when the plate was made in China they broke a tap where that screw would have threaded in. Their fix was not to remove the broken tap but to put a short screw in the roller and weld it from the backside so it looked fine but was really only held with one screw.

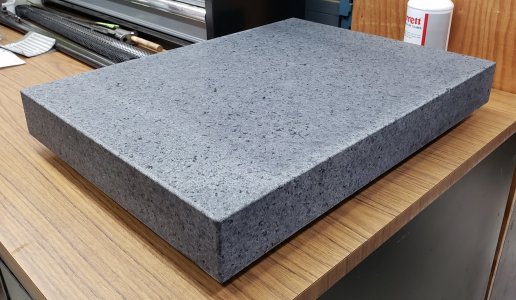

My friend acquired a used Starrett electronic deflection meters off Ebay. I believe its millionths reading. He made his own repeat-o-meter interface along the lines of what Rob.R did. Anyways he has a Busy Bee 12x18 granite surface plate & started mapping the topography for interest sake. Its within the stated 0.0001". Now whether that's a good one & the Friday model is the same is anyone's guess. He tested another fellows Lee Valley 9x12 & it wasn't as good, 2-3 tenths if I recall. But that's not suggesting one importer over another.

They are very reasonably priced but every time the sale come up in Calgary they show no stock. Sooner or later I will bite the bullet

www.busybeetools.com

www.busybeetools.com

They are very reasonably priced but every time the sale come up in Calgary they show no stock. Sooner or later I will bite the bullet

Buy Surface Plate 12" X 18" X 3" at Busy Bee Tools

The Surface Plate 12" x 18" x 3" is a precision tool designed to provide a stable and accurate reference surface for inspection, layout, and measurement tasks in metalworking and other precision engineering applications. Made from high-quality granite, this surface plate offers exceptional...

www.busybeetools.com

www.busybeetools.com

Now that I have a surface plate, I need to be able to measure stuff from it. I was going to get a Starrett surface gauge....until I saw the price! So I decided to use a test indicator stand, but I wanted a larger flat base. So I grabbed a hunk of steel, machined it on the mill, ground it on the surface grinder, then lapped the base. Attached the the stand to it, and we're good to go.

Attachments

It's the NOGA PH4016. Very solid, plus with that hunk of steel I made attached to it, its very stable.Very nice. Is that articulating arm & clamp on the vertical post a Noga accessory or something you made?