Hi all,

so I've got this Lorch LLN that I bought a couple years ago, recently I've had to use it a couple times to make a few small pins/shafts and it got me thinking that maybe it's time to actually tool up to make it more useful and less of a comedy item in my shop.

The parts I've used it for so far has been in the "would get lost in my other lathe's chip tray" kind of size - last weekend it was a pin 1.1mm dia x 3mm long or a M1.6 threaded insert 3mm max OD x 3mm length. So not quite watch part size stuff but small by my standards at least (I repair old camerasfor a hobby because I have alot of old cameras and they are always breaking and that's what these parts were for).

SO my question is: do any of you have any suggestions on where/what to get for decent but OK priced tooling for a machine like this? I think I will give PCB drills a try for small drills and skip buying a 100$ #61-80 set but I could use some pointers for the rest: boring bars / tap and die / ??? I guess I'm wondering if I should try some of the clock / watchmaker supply places since I know nothing about that world - or is that stuff all overpriced and I should look elsewhere?

my Lorch LLN (baujahr 1954) - it's very old timey and has plain spindle bearings but is probably the only machine in my shop that is not absolutely beaten to death

1.1 x 3mm pin - cleaning up the nub from parting

tapered axles for an injection moulded plastic gear from an instant film back

cheers,

Eugene

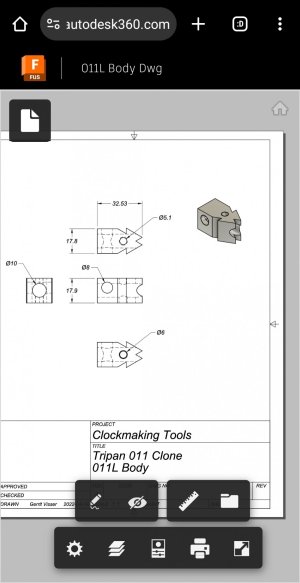

p.s. does anyone have a tripan 011 they would sell me so that I don't have to buy one from switzerland for like 400$ lol

so I've got this Lorch LLN that I bought a couple years ago, recently I've had to use it a couple times to make a few small pins/shafts and it got me thinking that maybe it's time to actually tool up to make it more useful and less of a comedy item in my shop.

The parts I've used it for so far has been in the "would get lost in my other lathe's chip tray" kind of size - last weekend it was a pin 1.1mm dia x 3mm long or a M1.6 threaded insert 3mm max OD x 3mm length. So not quite watch part size stuff but small by my standards at least (I repair old cameras

SO my question is: do any of you have any suggestions on where/what to get for decent but OK priced tooling for a machine like this? I think I will give PCB drills a try for small drills and skip buying a 100$ #61-80 set but I could use some pointers for the rest: boring bars / tap and die / ??? I guess I'm wondering if I should try some of the clock / watchmaker supply places since I know nothing about that world - or is that stuff all overpriced and I should look elsewhere?

my Lorch LLN (baujahr 1954) - it's very old timey and has plain spindle bearings but is probably the only machine in my shop that is not absolutely beaten to death

1.1 x 3mm pin - cleaning up the nub from parting

tapered axles for an injection moulded plastic gear from an instant film back

cheers,

Eugene

p.s. does anyone have a tripan 011 they would sell me so that I don't have to buy one from switzerland for like 400$ lol