I decided to finally build a shop press. Working on a meat slicer now and I need to remove a pressed bearing. Although I could go somewhere (a puller does not seem to even scare it), I am going to use up some material in the shop and make it into something useful other than a tripping hazard or fall threat! I have often wanted one but would not stop that project to build one. I am hoping to be able to do some press breaking with it too.

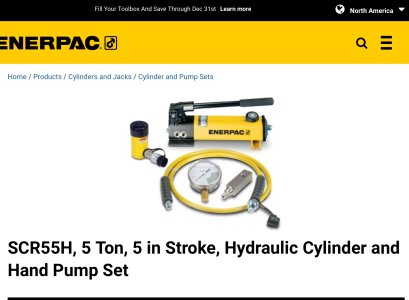

The posts and top are 2 x 3 x .250" tubing. The jack will be a 6 ton for now because I have one to prototype with but hoping (considering based on input here) to move to a pneumatic/hydraulic jack if all goes well when the press is done. Like this one but the 12 ton version (that page is not loading for me ) Is the pneumatic version good for this application or would the lack of "feel" or speed a bad thing for this application?

The holes are 9/16" right now. Question...how do I know or find the shear strength of a bolt/rod? For this application, I am thinking that 9/16" is lots. I was going to go 1" when I started planning but considering the tube is only 2" wide, that would not leave a lot of meat beside the hole.

The holes are 12" apart since the jacks have about 10" of travel, I figured this would be ok.

Input is good. I have not used presses very much.

Thanks

Shawn

The posts and top are 2 x 3 x .250" tubing. The jack will be a 6 ton for now because I have one to prototype with but hoping (considering based on input here) to move to a pneumatic/hydraulic jack if all goes well when the press is done. Like this one but the 12 ton version (that page is not loading for me ) Is the pneumatic version good for this application or would the lack of "feel" or speed a bad thing for this application?

The holes are 9/16" right now. Question...how do I know or find the shear strength of a bolt/rod? For this application, I am thinking that 9/16" is lots. I was going to go 1" when I started planning but considering the tube is only 2" wide, that would not leave a lot of meat beside the hole.

The holes are 12" apart since the jacks have about 10" of travel, I figured this would be ok.

Input is good. I have not used presses very much.

Thanks

Shawn

Attachments

Last edited: