Well, there seems to be a lot of members installing DRO's lately. Figured I would throw another thread on here rather than hijacking someone else's. In a previous thread on DRO's, I had mentioned purchasing the system from AliExpress a couple of months back and it (the project) finally came to the top of the list.

The mill is a Sieg X3 aka Grizzly G0463 aka others. Others have documented their installs onto similar machines so I was lucky in that I had some reference material to use. Grizzly has an install manual, DROPros do a video on a very similar machine (although they skip the Z axis which I thought would be the hardest, hence I tackled it first, before my enthusiasm waned), and several hobbyists on various forums have documented their installs.

On this mill, the main column has a shroud around it, that also contains the electronics in the back part. One guy, who went to the column directly, removed the shroud and then never bothered to put it back. He was CNCing his machine and moved his electronics anyways. Others attached to the shroud, which I did not like. One guy actually put his inside of the rear column. Nice to keep it clean but when I looked at that, well, nope! So I compromised. I attached to the main column with spacers that brought the mounts out to the exterior of the shroud. It seems to have worked out so far. I like the look of it. I am in the process of connecting the head to the scale now. I will need or want to put a gasket around the holes for the spacers. That was the closest sized hole saw I had, but, honestly, I usually miss my alignment so wanted some wiggle room. As it turned out they are fairly centered so I am pretty happy with that. I started to make square mounts to match the scales, but then realized it would be way easier to use a round post. They are tapped M8 on the back side, holding the mount to the column, then M5 on the front to hold the scale to the mount. Both were turned to the same length so I am hoping that aids in aligning that axis, assuming that if the posts are within a thous and attached directly to the column, then the scale should be in the same plane, I hope. If not, this method allows shimming easily. My scales do not have grub screws like some of the nicer ones so shims it is.

It is a bench top mill and my display goes on the wall so that works out OK. I am all excited just looking at it lit up.

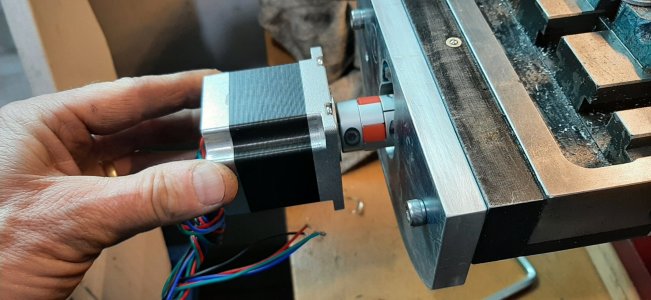

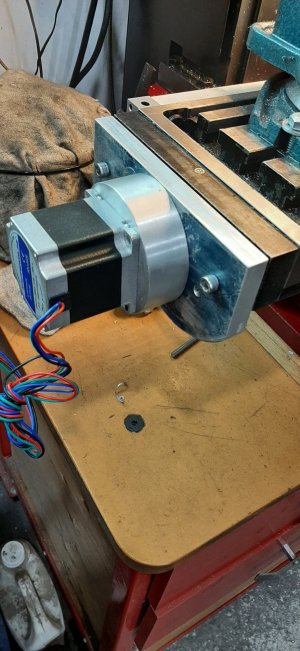

When I removed the shroud, I noticed how easy it would be to put a motor on the top of the lead screw (jack screw?) Maybe when I do the power feed, that option become one to be tackled.

Will report back tomorrow.

The mill is a Sieg X3 aka Grizzly G0463 aka others. Others have documented their installs onto similar machines so I was lucky in that I had some reference material to use. Grizzly has an install manual, DROPros do a video on a very similar machine (although they skip the Z axis which I thought would be the hardest, hence I tackled it first, before my enthusiasm waned), and several hobbyists on various forums have documented their installs.

On this mill, the main column has a shroud around it, that also contains the electronics in the back part. One guy, who went to the column directly, removed the shroud and then never bothered to put it back. He was CNCing his machine and moved his electronics anyways. Others attached to the shroud, which I did not like. One guy actually put his inside of the rear column. Nice to keep it clean but when I looked at that, well, nope! So I compromised. I attached to the main column with spacers that brought the mounts out to the exterior of the shroud. It seems to have worked out so far. I like the look of it. I am in the process of connecting the head to the scale now. I will need or want to put a gasket around the holes for the spacers. That was the closest sized hole saw I had, but, honestly, I usually miss my alignment so wanted some wiggle room. As it turned out they are fairly centered so I am pretty happy with that. I started to make square mounts to match the scales, but then realized it would be way easier to use a round post. They are tapped M8 on the back side, holding the mount to the column, then M5 on the front to hold the scale to the mount. Both were turned to the same length so I am hoping that aids in aligning that axis, assuming that if the posts are within a thous and attached directly to the column, then the scale should be in the same plane, I hope. If not, this method allows shimming easily. My scales do not have grub screws like some of the nicer ones so shims it is.

It is a bench top mill and my display goes on the wall so that works out OK. I am all excited just looking at it lit up.

When I removed the shroud, I noticed how easy it would be to put a motor on the top of the lead screw (jack screw?) Maybe when I do the power feed, that option become one to be tackled.

Will report back tomorrow.