So I've been pucking around with an Arduino-based calculator to calculate SFM / RPM for different material for my lathe and mill. I have a version that works for the mill, and in the process of putting together one for the lathe.

Here's the mill version. Two dials, one sets material, one selects cutter diameter.

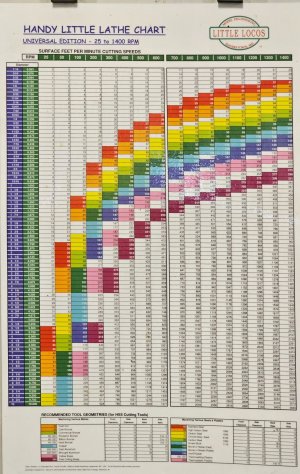

Tonight, assembling the lathe version, while sticking jumper wires into a proto board, I managed to fry some pixels on the LCD display I'm using. No big deal, the display is worth $8. Then I started thinking, this is dumb. The math is pretty simple, I can do simple math in my head, and I have some very nice engraving machines. A 3"x5" chunk of 16ga aluminum and an Excel spreadsheet makes a RPM SFM chart that won't ever burn out, short when hit with cutting fluid, and if it gets scratched to poop I can just make a new one.

Excel chart:

I'll post a photo of a completed plate once I have one done.

Here's the mill version. Two dials, one sets material, one selects cutter diameter.

Tonight, assembling the lathe version, while sticking jumper wires into a proto board, I managed to fry some pixels on the LCD display I'm using. No big deal, the display is worth $8. Then I started thinking, this is dumb. The math is pretty simple, I can do simple math in my head, and I have some very nice engraving machines. A 3"x5" chunk of 16ga aluminum and an Excel spreadsheet makes a RPM SFM chart that won't ever burn out, short when hit with cutting fluid, and if it gets scratched to poop I can just make a new one.

Excel chart:

I'll post a photo of a completed plate once I have one done.