Matt-Aburg

Ultra Member

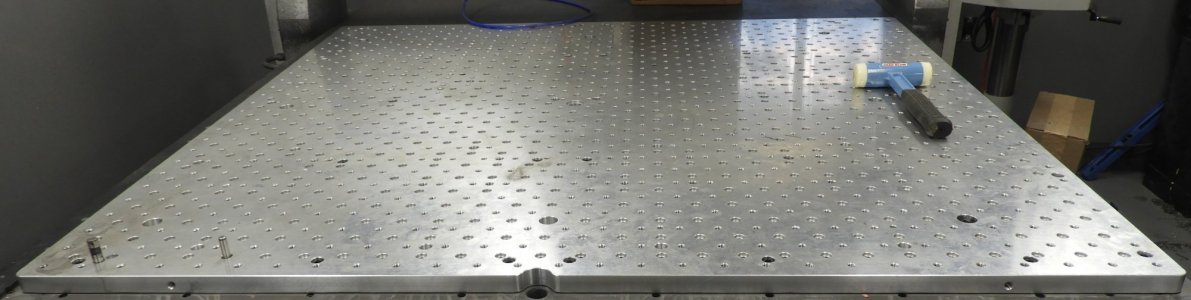

I have built a large fixture plate for my CNC router. It has about 650 3/8-16 holes in it. I originally purchased plastic setscrews because of corrosion concerns. Unfortunately, these setscrews are made out of PP and are a class 1A- 2A thread. After 4 turns into the plate the Hex strips and then they are scrap. I called Grainger today and was refunded in full and don't even have to return the warranty items.

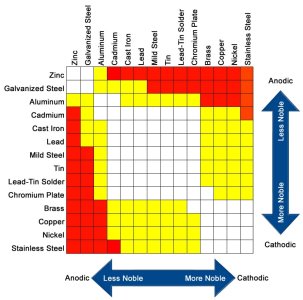

Moving on, I talked to a rep and he suggested using Stainless setscrews. I have read that stainless still will react with aluminum. Other sources say to use zinc plated. Still other sources say the Zinc will corrode and be a big mess. (eventually).....

Here is my thoughts The Zinc plated setscrews cost about 4 times more than stainless. I could dip the stainless setscrews in lithium to reduce the contact with the aluminum plate. Note also that the setscrews (both) are class 3A...

Any thoughts or opinions would be appreciated, before I pull the trigger.

Moving on, I talked to a rep and he suggested using Stainless setscrews. I have read that stainless still will react with aluminum. Other sources say to use zinc plated. Still other sources say the Zinc will corrode and be a big mess. (eventually).....

Here is my thoughts The Zinc plated setscrews cost about 4 times more than stainless. I could dip the stainless setscrews in lithium to reduce the contact with the aluminum plate. Note also that the setscrews (both) are class 3A...

Any thoughts or opinions would be appreciated, before I pull the trigger.

Attachments

Last edited: