I was using my new tap handles by making some new thread cutters out of 1/8 plate. In doing so I realized that I have a thread checker I use all the time that I don't think we have ever discussed. Maybe I'm wrong.

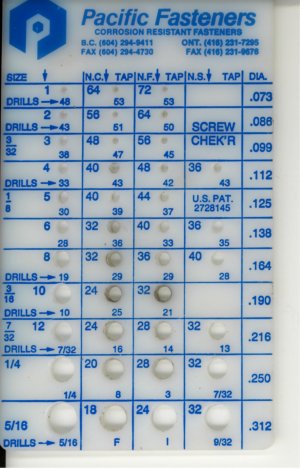

But anyway, this little "Screw Checker" is available at many suppliers (even Amazon) in both metric and imperial versions. It is a VERY useful plate.

First you take the subject screw and find the best fit on the left side to identify the diameter. Then you can find the thread pitch by trying it in each of the holes to the right. It isn't as perfect as a thread gauge because it only uses a thin plate, but in practice it still works awesome!

There is also some other useful info on the plate including drill size.

Can you tell I use a lot of 8-40 and 6-48 screws???

The two deformations at the top right were the result of using the wrong tool to straighten a small tanged plate in a hydraulic press. Live and learn. I'd replace the gauge plate, but it's a good reminder to always use the proper tool because I keep this plate its metric sister nice and handy.

But anyway, this little "Screw Checker" is available at many suppliers (even Amazon) in both metric and imperial versions. It is a VERY useful plate.

First you take the subject screw and find the best fit on the left side to identify the diameter. Then you can find the thread pitch by trying it in each of the holes to the right. It isn't as perfect as a thread gauge because it only uses a thin plate, but in practice it still works awesome!

There is also some other useful info on the plate including drill size.

Can you tell I use a lot of 8-40 and 6-48 screws???

The two deformations at the top right were the result of using the wrong tool to straighten a small tanged plate in a hydraulic press. Live and learn. I'd replace the gauge plate, but it's a good reminder to always use the proper tool because I keep this plate its metric sister nice and handy.