Jswain

Joe

So I recently picked up a Craftex ct129n mill and it came with an STM 6" rotary table. Looking to make use of the 3/4 jaw + collet chuck I have for my Southbend which are 1-1/2" x 8tpi thread on.

My rotary table has a threaded center, and from what I've read using it to mount a chuck is less desirable. So I am thinking of cutting out a chunk of 3/4" plate for the mount, then I have some ~ 1-3/4" rod I could bore the center of the plate, press in & weld. Turn down and thread for 1-1/2 x 8tpi

Could probably use a clamp kit on the face of the chuck to keep it from turning if needed? Any of you guys make one of these for thread on chucks, or is there a better way? Thanks!

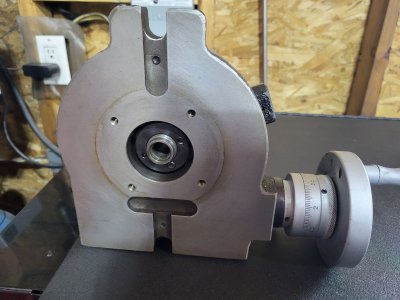

Basically looking to imitate this

My rotary table has a threaded center, and from what I've read using it to mount a chuck is less desirable. So I am thinking of cutting out a chunk of 3/4" plate for the mount, then I have some ~ 1-3/4" rod I could bore the center of the plate, press in & weld. Turn down and thread for 1-1/2 x 8tpi

Could probably use a clamp kit on the face of the chuck to keep it from turning if needed? Any of you guys make one of these for thread on chucks, or is there a better way? Thanks!

Basically looking to imitate this

Attachments

Last edited: