Downwindtracker2

Well-Known Member

I bought a couple of project machines off a cabinetmaker , a RongFu RF-45 mill drill and a DF1224g lathe. They were for some design he was going to build. He said the RF-45 had been used as a CNC. At work they had bought a new RF-45 for the maintenance shop, so knew the model. They are a nice size for a garage work shop. My gunsmith friend has one and does great work on his. Good machines. Mine needed a handle just to stop the feed screw from screwing out. Once Grizzly parts were on it, it worked . If I was light about the cuts. But even so, it paid for itself in home projects I wouldn't have been able to do without it. I find mills handier than lathes.

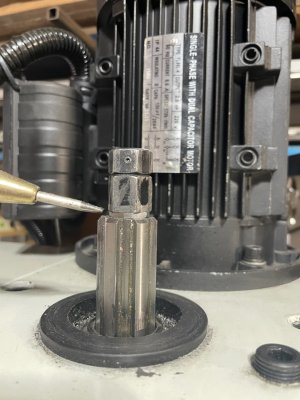

But It needed mechanical and electrical repairs. For me,mechanical was easy , I replaced the feed screws and nuts. Thomas Skinner imported it and was still able to get parts.I doubt it now. There was no adjustment left in the nuts. I made a stop for travel and a center T. And a pointer for the quill depth. My red paint stick pen is really a dark pink ! looks good against the grey face. Electrical was a different story, the light switch didn't inspire confidence nor give reverse. I couldn't sort out the motor wiring for a drum switch , so I took it to a motor shop. It gave him fits too, but he got it. The motor got a check over as well. I added a mag starter ahead of the drum switch.

Now I have a fully fuctional RF-45. It's not pretty, but it's tight and smooth. I'm so pleased, I just had to post.

But It needed mechanical and electrical repairs. For me,mechanical was easy , I replaced the feed screws and nuts. Thomas Skinner imported it and was still able to get parts.I doubt it now. There was no adjustment left in the nuts. I made a stop for travel and a center T. And a pointer for the quill depth. My red paint stick pen is really a dark pink ! looks good against the grey face. Electrical was a different story, the light switch didn't inspire confidence nor give reverse. I couldn't sort out the motor wiring for a drum switch , so I took it to a motor shop. It gave him fits too, but he got it. The motor got a check over as well. I added a mag starter ahead of the drum switch.

Now I have a fully fuctional RF-45. It's not pretty, but it's tight and smooth. I'm so pleased, I just had to post.