a smile

Lifelong hobby - cold iron

Some time ago, I was exhausted by Amazon, and finally began to normal. Now I began to return to the status of iron filings flying.

A drill machine acquired about 3 years ago, finally had time to start renovating. Edge to repair the process on the edge, I don't know whether can perfect repair, also hope to get experienced support, thank you for the first -- -- -- -- -- -- -- -- -- --

This is the original look

The workbench was badly damaged

The motor was tested to be serviceable, but the gearbox was apparently broken

I hope it can be restored, and it must be beautiful. So dismantling it is a necessary process.

The lifting arm is apparently out of service, temporary repairs will allow it to complete the lifting function - May 14, 2023

Let's break it down into some big parts

Clean and polish the base

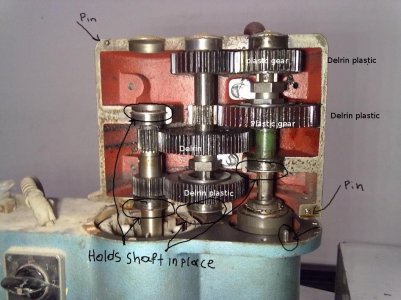

The process of dismantling the gearbox in between

Buy putty, paint, and airbrush in advance,

Clean and clean the gear box after disassembling (it will be updated continuously as of today)

A drill machine acquired about 3 years ago, finally had time to start renovating. Edge to repair the process on the edge, I don't know whether can perfect repair, also hope to get experienced support, thank you for the first -- -- -- -- -- -- -- -- -- --

This is the original look

The workbench was badly damaged

The motor was tested to be serviceable, but the gearbox was apparently broken

I hope it can be restored, and it must be beautiful. So dismantling it is a necessary process.

The lifting arm is apparently out of service, temporary repairs will allow it to complete the lifting function - May 14, 2023

Let's break it down into some big parts

Clean and polish the base

The process of dismantling the gearbox in between

Buy putty, paint, and airbrush in advance,

Clean and clean the gear box after disassembling (it will be updated continuously as of today)