Hi Everybody,

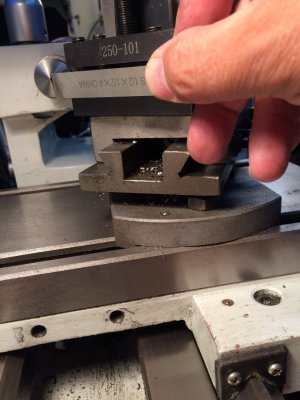

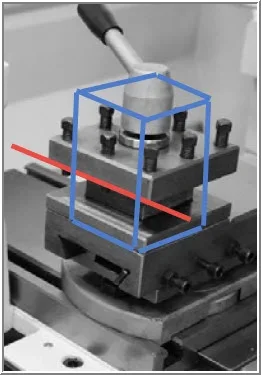

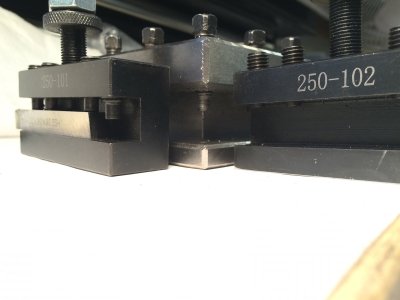

I finally have my quick change tool post (AXA size, wedge type) from Accusizetools.ca mounted on my lathe. This replaces the stock 4 position turret tool post. It works well, I am quite pleased. However, since my lathe (CX701 from BusyBee) has kind of a different type of compound the tool post does not mount in the normal manner with a T-Nut.. This has led to problem where the tools can't be lowered quite enough to get to the centre of work in some cases. e.g. the parting tool and 1/2" bits. 3/8" bits are fine. See pictures.

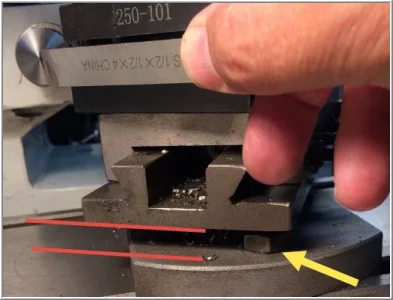

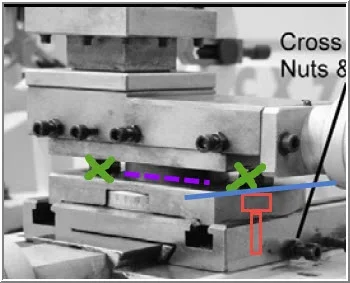

I could make a irreversible modification to the compound and remove about 1/2 inch of material from the end of the dove tail slide. This would allow the tool holders to be mounted lower and solve the centre height problem. Two variations. One I could take all the material off and make it square. Options two perhaps just remove 3/8" or so leaving some material for rigidity. I drew a red box around where I could remove material.

Thoughts?

I finally have my quick change tool post (AXA size, wedge type) from Accusizetools.ca mounted on my lathe. This replaces the stock 4 position turret tool post. It works well, I am quite pleased. However, since my lathe (CX701 from BusyBee) has kind of a different type of compound the tool post does not mount in the normal manner with a T-Nut.. This has led to problem where the tools can't be lowered quite enough to get to the centre of work in some cases. e.g. the parting tool and 1/2" bits. 3/8" bits are fine. See pictures.

I could make a irreversible modification to the compound and remove about 1/2 inch of material from the end of the dove tail slide. This would allow the tool holders to be mounted lower and solve the centre height problem. Two variations. One I could take all the material off and make it square. Options two perhaps just remove 3/8" or so leaving some material for rigidity. I drew a red box around where I could remove material.

Thoughts?