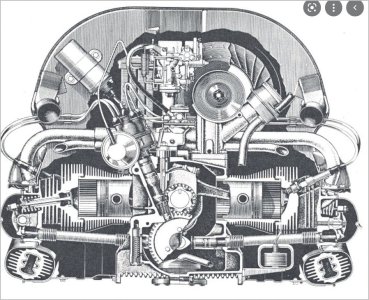

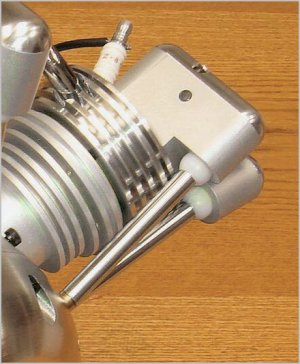

Motor guys: On engines with pushrod tubes like the stainless ones (maybe they are called 'windage' tubes?)

- does the accordion section allow some minor bending or deviation of the tube axis like when the pushrod has to act at a 3D angle from the tappet to the rocker arm?

- or is the accordion more intended like a spring to exerting a bit of axial force to keep the tube in position?

- I assume the accordion has a formed uniform section, as opposed to just grooves cut in? (guessing grooves would fatigue & crack).

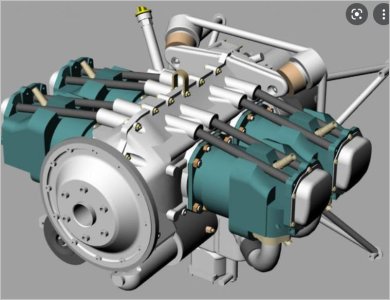

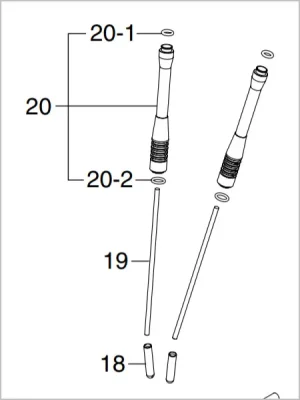

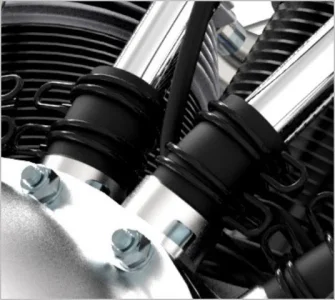

These anodized ones look different. Looks like they have curved rubber seal on both ends & the tube telescopes with a spring to keep them engaged. I can see how this would make installation a bit easier but again mostly I'm wondering if those seals are meant to allow the tube ends to be at a 3D angle to one another?

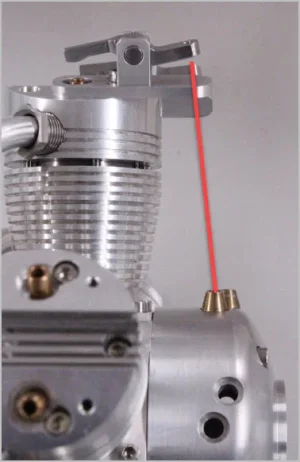

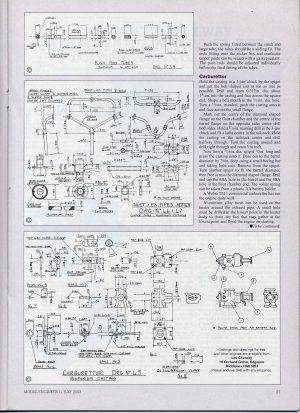

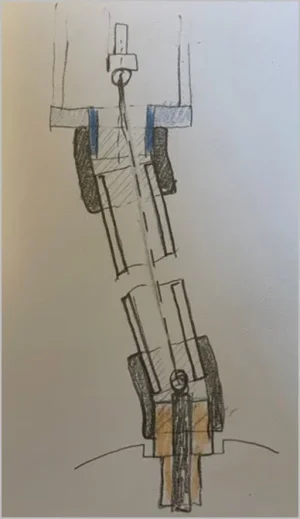

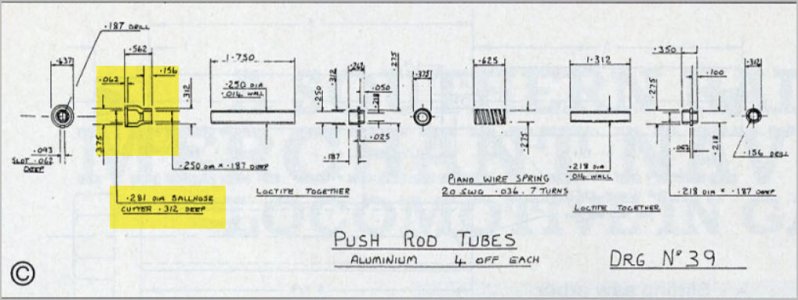

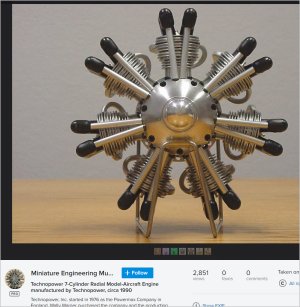

The problem I'm trying to solve on my radial is similar pushrod tubes. The design calls for the tube to overlap the cone shaped tappet bushing at its angle, then a funky 3D hole angle through the bottom of rocker perch held with a teeny set screw. Seems iffy to me on multiple fronts. I would ideally like something rubberized on both ends rather than metal on metal. Dimensionally the tube is only about 0.250" OD x .015" wt x 2" length so kind of finicky small scale.

- does the accordion section allow some minor bending or deviation of the tube axis like when the pushrod has to act at a 3D angle from the tappet to the rocker arm?

- or is the accordion more intended like a spring to exerting a bit of axial force to keep the tube in position?

- I assume the accordion has a formed uniform section, as opposed to just grooves cut in? (guessing grooves would fatigue & crack).

These anodized ones look different. Looks like they have curved rubber seal on both ends & the tube telescopes with a spring to keep them engaged. I can see how this would make installation a bit easier but again mostly I'm wondering if those seals are meant to allow the tube ends to be at a 3D angle to one another?

The problem I'm trying to solve on my radial is similar pushrod tubes. The design calls for the tube to overlap the cone shaped tappet bushing at its angle, then a funky 3D hole angle through the bottom of rocker perch held with a teeny set screw. Seems iffy to me on multiple fronts. I would ideally like something rubberized on both ends rather than metal on metal. Dimensionally the tube is only about 0.250" OD x .015" wt x 2" length so kind of finicky small scale.