I have noticed more than a few of these hinge type boxes which, if I understand, is a single plate print. I have yet to try a download, but just wondering if anyone has experience with the print & end result. Does it print with support in between the male/female hinge surfaces, then goes crunch the first time you operate the hinge (breaking supports) & thereafter moves freely? (Which mitigates adding roll pins or equivalent as hinge pins).

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Print in place hinge mechanism

- Thread starter PeterT

- Start date

Hi Peter can you post the link to the design your looking at printing. There are a couple calibration designs to setup for print in place. Two that come to mind is the torture toaster and the clearance castle.

www.printables.com

www.printables.com

The Torture Toaster by Clockspring | Download free STL model | Printables.com

An articulated torture test model featuring toast! | Download free 3D printable STL models

Dan Dubeau

Ultra Member

One of the very first things I designed and printed when I got my first Anet printer was a simple print in place hinge. There is no support, just clearance in the cad model between the two part. Essentially leaving a gap big enough that the filament wont bond with the previous layer. I think I settled on 0.25 for mine, but I can't remember it's been a while. There are models you can download that have various features designed at various clearances so you can test your own printer and settings so you can easily achieve your desired effect. I think I printed a few different hinges at various clearances before finding a sweet spot where the hinge worked.

I kept it as a desk fidget toy for many years, until I ultimately broke it. But even after all those repetitions it still worked, and the layered effect had a distinct snapping effect on closure. I just went and found it, and will upload it if you/anybody wants to try printing it.

I kept it as a desk fidget toy for many years, until I ultimately broke it. But even after all those repetitions it still worked, and the layered effect had a distinct snapping effect on closure. I just went and found it, and will upload it if you/anybody wants to try printing it.

Attachments

Ack! I found that model in Bambu Makerworld. When I tried to click it to get a link, it launched itself into my Bambu Studio Slicer, so still don't have the link & now I don't see it. Now I cant recall what specific search keywords I was originally using.

I tried again with 'hinged box' & even more came up like this, generically similar. Maybe I will just find a small one, download & try. Mostly I was interested to generate one on my own. This is still a confusing thing to me. If the box & lid are 2 separate bodies in CAD (with clearance between pin & hole), do I assemble them within CAD so they are spaced accordingly & then somehow import that assembly into slicer to preserve the orientation as a single build plate? I still don't see how it could print without supports. Maybe I should just focus on a hinge first LOL.

I tried again with 'hinged box' & even more came up like this, generically similar. Maybe I will just find a small one, download & try. Mostly I was interested to generate one on my own. This is still a confusing thing to me. If the box & lid are 2 separate bodies in CAD (with clearance between pin & hole), do I assemble them within CAD so they are spaced accordingly & then somehow import that assembly into slicer to preserve the orientation as a single build plate? I still don't see how it could print without supports. Maybe I should just focus on a hinge first LOL.

Dan thanks for posting I have a simple box design I was looking for a hinge for it. Ah the anet years when we valued creativity over fire safety.One of the very first things I designed and printed when I got my first Anet printer was a simple print in place hinge. There is no support, just clearance in the cad model between the two part. Essentially leaving a gap big enough that the filament wont bond with the previous layer. I think I settled on 0.25 for mine, but I can't remember it's been a while. There are models you can download that have various features designed at various clearances so you can test your own printer and settings so you can easily achieve your desired effect. I think I printed a few different hinges at various clearances before finding a sweet spot where the hinge worked.

I kept it as a desk fidget toy for many years, until I ultimately broke it. But even after all those repetitions it still worked, and the layered effect had a distinct snapping effect on closure. I just went and found it, and will upload it if you/anybody wants to try printing it.

Dan Dubeau

Ultra Member

Someday I will own a printer I feel safe leaving to print overnightDan thanks for posting I have a simple box design I was looking for a hinge for it. Ah the anet years when we valued creativity over fire safety.

Nothing like a 60 hour print to keep you slightly awake for 3 days! Waiting for the light wisp of smoke to wake you at 3am. The good old days of 3d printing Best part of the high speed printers is that 60 hours is now 15.Someday I will own a printer I feel safe leaving to print overnight

Dan Dubeau

Ultra Member

I detached a smoke detector from the ceiling, and rigged it above the printer one night when I first got it because I was worried about it lol. I never really did much of unattended printing. I blows my mind the speed at which the new generation prints at and how safe and reliable they are. I really should get one.....

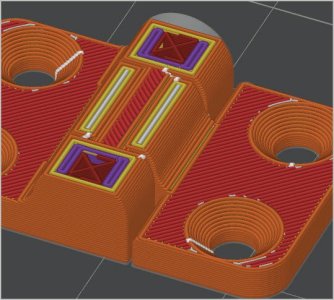

@Dan Dubeau I printed your hinge model laying flat like this. Very cool. It did not I suggest supports which I kind of understand now looking at the sectional slice, there is always infill material present but it just omits the clearance gap which is of course what you want for a hinge. I'll have to replicate this workflow in my CAD modeler, opens up a whole new world.

Attachments

Dan Dubeau

Ultra Member

Awesome. How did the clearance come out on your printer? Did it take a light snap to free the hinge, or did it come off already free?

A tiny crackle & it rotates perfectly free. Well, as smooth as can be expected by printed striations of what are theoretical round parts, axle & hole. I didn't realize till I printed it, has an integrated stop profile so it's 0-180 hinge. My setting is 0.2mm on 0.4 nozzle. I'd take a pic but I'm using black filament & doesnt photo too well. So I think the basic design could be adapted into a single print box & lid like the example pics. But I'm going to make a little tester that uses say M3 roll pins just for comparison. Extra parts but maybe smoother action? Thanks Dan!