-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Princess deals

- Thread starter Janger

- Start date

Jimbojones

Active Member

Wanted to let the gang know: These pickup tools were reg $18 @ PA and they are discontinued....went under$7 then they marked it down ANOTHER 75%....I think it cost $1.80 (should have bought more and handed them out a presents)

Last edited:

Jimbojones

Active Member

Anyone know of any other MUST HAVE tools from PA for a metal shop? I get invited to the private xmas shopping party and get some nice discounts...I try to make a list and keep an eye open and then the next day,

remember something I should have bought and swear at myself because I have to wait another year.

Already have compressor (60g single stage....is a 2-stage useful for home use?) , welder and cutter, sockets, taps/dies, grinders and drills galore... so that's mostly covered

For instance, I was going to check out was a cold/dry saw: I think they disco'd the PowerFist model and replaced with ProPoint model (and price went up 50%).

Considering I already have 7x12 bandsaw:

1) would a cold saw be a useful addition?

2) are the ones they make any good (since they sell for about 1/2 to 2/3 what everyone else sells a similar saw for). Also, they list it @ 2400W and 110v...sounds like a 20A circuit is required

Also pondering an air-over-hydraulic press (12-20ton) ...but have very little use for one and they take up lots of space

Any other tools that a shop 'just can't be without'?

remember something I should have bought and swear at myself because I have to wait another year.

Already have compressor (60g single stage....is a 2-stage useful for home use?) , welder and cutter, sockets, taps/dies, grinders and drills galore... so that's mostly covered

For instance, I was going to check out was a cold/dry saw: I think they disco'd the PowerFist model and replaced with ProPoint model (and price went up 50%).

Considering I already have 7x12 bandsaw:

1) would a cold saw be a useful addition?

2) are the ones they make any good (since they sell for about 1/2 to 2/3 what everyone else sells a similar saw for). Also, they list it @ 2400W and 110v...sounds like a 20A circuit is required

Also pondering an air-over-hydraulic press (12-20ton) ...but have very little use for one and they take up lots of space

Any other tools that a shop 'just can't be without'?

@Janger Good call on the Furnace. The things I like buying at PA are the small stuff I need to finish my projects. I don't know where else I can even go to get pulleys, belts, air fittings, hydraulic cylinders and blank sprockets. All of the bigger power tools and consumer products I usually buy elsewhere. That being said I mounted a PA crane in the back of my truck and I would do it again.

Jimbojones

Active Member

Furnace/heater - CHECK

I've got a dry cut from there for years ago.. they are not cold saws, just dry. I built a lot of things over the years with it but I wouldn't recommend it to anyone, leaves a burr and it's got a shitty edge once cut. They also tend to wander pretty bad and don't like cutting anything that's thick. I had a broken bandsaw for a whole and used mine to cut 2x5 aluminum and it tripped the breaker 5 times going through and took longer than my only tiny bandsaw. Not worth it in my opinion.

Having said that it seems like a lot of people have had good experience with Dewalt saws - check out what NYC cnc is doing since they sell a clamping table for their saw and they seem to use it all the time. May be a better option.

Having said that it seems like a lot of people have had good experience with Dewalt saws - check out what NYC cnc is doing since they sell a clamping table for their saw and they seem to use it all the time. May be a better option.

I have one of these - dry cut - it’s loud cutting metal and sprays hot swarf but works quite well. https://www.amazon.ca/Evolution-Power-Tools-RAGE3-Multipurpose/dp/B0030M2TCC

Pretty clean cuts. Miter feature is handy. You must must must clamp the material well or horrible kickbacks occur. It cost less a few years ago... like everything. I have have their circular saw too. Both say 1/4” max but I’ve cut 1/2” without issue. The blades in these saw spin slower - I think that helps.

The dewalt saws look nice too - they don’t miter as easily - turn the material not the saw, and pricey but typical for the class. I agree Kyle they look good and that cutting table nyc makes is interesting. When you see him use that saw in the show you can tell he he’s had some experiences he says it’s a dangerous saw and you must clamp well. There’s a nice Fein saw in this class too at kms it’s even more money.

Pretty clean cuts. Miter feature is handy. You must must must clamp the material well or horrible kickbacks occur. It cost less a few years ago... like everything. I have have their circular saw too. Both say 1/4” max but I’ve cut 1/2” without issue. The blades in these saw spin slower - I think that helps.

The dewalt saws look nice too - they don’t miter as easily - turn the material not the saw, and pricey but typical for the class. I agree Kyle they look good and that cutting table nyc makes is interesting. When you see him use that saw in the show you can tell he he’s had some experiences he says it’s a dangerous saw and you must clamp well. There’s a nice Fein saw in this class too at kms it’s even more money.

Last edited:

I bought the batteries too. Some are odd sizes good to have on hand.

My latest was the PA 2 Ton Chain Hoist

My latest was the PA 2 Ton Chain Hoist

No worries and thanks @Dabbler. I appreciate it.

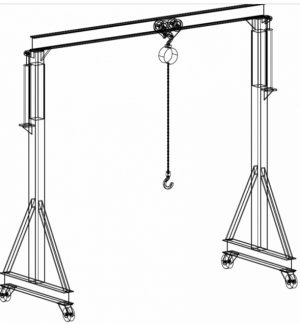

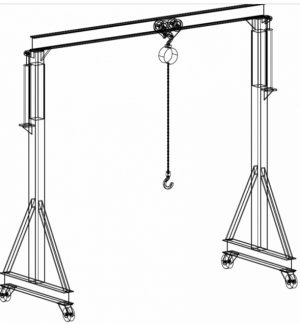

I had a store credit I used for the 2 Ton trolley. The chain hoist was on sale this week at PA. All in—$22.19. Best of all I found some great plans online—almost EXACTLY what I had been envisioning myself. The improvement in my design plans was the 20" hydraulic long travel jacks on the side posts to raise past my limited garage door opening and ceiling. I love the jack feature--especially after my experience of renting a gantry this year. I realized I can't raise the posts myself w/o a helper. Sucks being old. Justin should cry some tears for me, but perfect for my situation!

Originally I was looking at a scaffolding/screw jack mod, but the long travel jacks go on sale regularly at PA, and I have an app watching for a sale to complete the materials list. So...Bob's your (creepy) uncle...for those who get the reference.

I am building in a way that when the Grim Reaper calls and I need to downsize there will be resale value: 4400 lbs., probably more. (FYI: a Honda Fit is only about 1900 lbs.) The height will be extensible past my ceiling height, plus, it will span a 3/4 ton F250. I'll design the telescoping components so that they can be additive and function in a shop with a higher ceiling by pegging the moveable rod ends.

I bought the plans off Gizmo Plans for $19 USD. The mod I envision relates to indexable/adjustable rod end tangs that will permit operation in low clearance situation—yet allow for resale for larger shops because it can be indexed. I'll build so that the telescoping posts can accommodate a higher ceiling. For comparison, the equivalent EME crane is $7000 CND plus outrageous shipping. Really outrageous..like $850 CND.

I had a store credit I used for the 2 Ton trolley. The chain hoist was on sale this week at PA. All in—$22.19. Best of all I found some great plans online—almost EXACTLY what I had been envisioning myself. The improvement in my design plans was the 20" hydraulic long travel jacks on the side posts to raise past my limited garage door opening and ceiling. I love the jack feature--especially after my experience of renting a gantry this year. I realized I can't raise the posts myself w/o a helper. Sucks being old. Justin should cry some tears for me, but perfect for my situation!

Originally I was looking at a scaffolding/screw jack mod, but the long travel jacks go on sale regularly at PA, and I have an app watching for a sale to complete the materials list. So...Bob's your (creepy) uncle...for those who get the reference.

I am building in a way that when the Grim Reaper calls and I need to downsize there will be resale value: 4400 lbs., probably more. (FYI: a Honda Fit is only about 1900 lbs.) The height will be extensible past my ceiling height, plus, it will span a 3/4 ton F250. I'll design the telescoping components so that they can be additive and function in a shop with a higher ceiling by pegging the moveable rod ends.

I bought the plans off Gizmo Plans for $19 USD. The mod I envision relates to indexable/adjustable rod end tangs that will permit operation in low clearance situation—yet allow for resale for larger shops because it can be indexed. I'll build so that the telescoping posts can accommodate a higher ceiling. For comparison, the equivalent EME crane is $7000 CND plus outrageous shipping. Really outrageous..like $850 CND.

Last edited:

Jimbojones

Active Member

Wanted to get more PA ideas....

What about stationary belt/disk sander? Seen guys use these for metal work but had some questions:

- I thought that many of these were mainly for woodwork. Would the rollers and belts stand up to use on metal?

- these come in many different configurations.

- smallest is like 1" belt x 5" disk or 2 x 6; useful for knife makers but not sure it would be useful overall

- then you get 1x6 or 2x8 units. PA only carries the smaller models of these and again, not sure they're durable

I do have bench grinders but I find that it's hard to finesse the grinding and thought the belt approach w/table would be more versatile.

What are others using to fill this need?

What about stationary belt/disk sander? Seen guys use these for metal work but had some questions:

- I thought that many of these were mainly for woodwork. Would the rollers and belts stand up to use on metal?

- these come in many different configurations.

- smallest is like 1" belt x 5" disk or 2 x 6; useful for knife makers but not sure it would be useful overall

- then you get 1x6 or 2x8 units. PA only carries the smaller models of these and again, not sure they're durable

I do have bench grinders but I find that it's hard to finesse the grinding and thought the belt approach w/table would be more versatile.

What are others using to fill this need?

There is some good intell in this thread.

I've had many sanders over the years and despite warning in manuals it wasn't until recently I got my first devoted metal machines, an Ellis and the Kalamazoo in the thread above. One of the best I had was an old Crappy Tire 8" disk for wood that lasted years and years for metalwork. It did great.

Assuming it isn't under powered, the best thing you can do is use the blue Zirconia belts instead of plain wood (AL oxide) ones. The King manuals from KMS say use on metal is fine.

I did see a fire start in one once only because the operator used it for both wood and metal. The sawdust gets clogged in the discharge and it caught on fire. It spread to the plastic Shop Vac hose. No biggie, just use common sense and either keep it clean or don't use it for both. Never use plastic discharge hoses for metal sanding.

I rarely use my grinder any more, other than the wire wheel on the other spindle. Sanding is much nicer.

Best of luck.

I've had many sanders over the years and despite warning in manuals it wasn't until recently I got my first devoted metal machines, an Ellis and the Kalamazoo in the thread above. One of the best I had was an old Crappy Tire 8" disk for wood that lasted years and years for metalwork. It did great.

Assuming it isn't under powered, the best thing you can do is use the blue Zirconia belts instead of plain wood (AL oxide) ones. The King manuals from KMS say use on metal is fine.

I did see a fire start in one once only because the operator used it for both wood and metal. The sawdust gets clogged in the discharge and it caught on fire. It spread to the plastic Shop Vac hose. No biggie, just use common sense and either keep it clean or don't use it for both. Never use plastic discharge hoses for metal sanding.

I rarely use my grinder any more, other than the wire wheel on the other spindle. Sanding is much nicer.

Best of luck.

You beat me to the sawdust + metals sparks = campfire potential. I was using my belt sander for minor steel part chamfering & detected an odor of smoke. Sure enough. Now I vacuum out the sawdust beforehand. Seems so obvious in hindsight.

+1 on the blue zirconia. My brown (aluminum oxide?) woodworking belts generally die on metal although I know there is good quality belts & also junk grade.

+1 on the blue zirconia. My brown (aluminum oxide?) woodworking belts generally die on metal although I know there is good quality belts & also junk grade.