Thoughts / suggestions gladly accepted.

I have a Busy Bee B2227L lathe. The gearhead part is great, the lead screw change gear is a true pain in the bum.

I rarely cut threads, mostly I use the power feed for turning down shafts.

No matter what gear set I have installed, it never seems to be the right feed rate. So I’m constantly removing and replacing greasy gears.

I lust after a lathe that has both gearhead for spindle speed, and quick change gears for lead screw, but the only ones I can find are 12x36 and too big to fit in my shop. And I want true speed changes, not variable speed drive.

The B2227L has a handwheel on the lead screw, with a spring-loaded dog clutch. I’m contemplating replacing the handwheel with a gear motor / dog clutch combination.

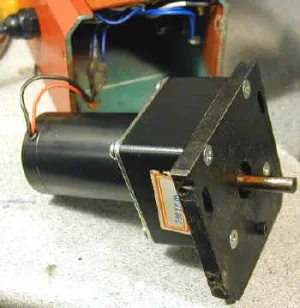

I have a left-over mini mill power feed, one of these:

It runs at maximum 200 RPM, and puts out more than enough torque to spin the leadscrew. I’d make up a bracket and hang it off the right hand end off the lathe.

I tried to come up with a way to interface the gear motor with the change gear set at the headstock, but it’s just too complicated to make work. I’ve seen it done on a 7x12, but the 7x12s have a different arrangement for change gears.

Has anybody else come up with a better solution to get multiple feed rates without buying a new lathe?

I have a Busy Bee B2227L lathe. The gearhead part is great, the lead screw change gear is a true pain in the bum.

I rarely cut threads, mostly I use the power feed for turning down shafts.

No matter what gear set I have installed, it never seems to be the right feed rate. So I’m constantly removing and replacing greasy gears.

I lust after a lathe that has both gearhead for spindle speed, and quick change gears for lead screw, but the only ones I can find are 12x36 and too big to fit in my shop. And I want true speed changes, not variable speed drive.

The B2227L has a handwheel on the lead screw, with a spring-loaded dog clutch. I’m contemplating replacing the handwheel with a gear motor / dog clutch combination.

I have a left-over mini mill power feed, one of these:

It runs at maximum 200 RPM, and puts out more than enough torque to spin the leadscrew. I’d make up a bracket and hang it off the right hand end off the lathe.

I tried to come up with a way to interface the gear motor with the change gear set at the headstock, but it’s just too complicated to make work. I’ve seen it done on a 7x12, but the 7x12s have a different arrangement for change gears.

Has anybody else come up with a better solution to get multiple feed rates without buying a new lathe?