Hey everyone,

I have very horrible power service at my property. I have a 7000 whisper watt diesel generator that I thought could use on my lathe.

The other night I plugged it in and the power light came on but the lathe would turn on and spin. So now I've been down tons of rabbit holes reading about start up power etc. I'm starting to think my generator won't work for this task. I'm still going to check a few things, like fuses, breakers and what not.

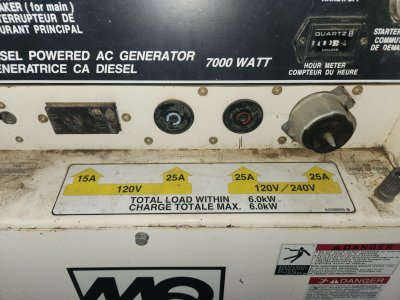

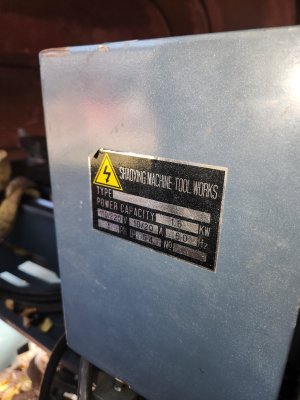

I'm not an electrician so lots of this is a 3rd language to me. I have a decent understanding but I'm wondering if wired the lathe for 120, if my generator would work then. It's currently wired for 220, I can't remember the size of the motor. For the generator 220 plug in is rated for 240 with 25amp. The 120 side is 120 with 25amp.

My question is would the start up draw be lower if I had it wired for 120?

I added some pictures so maybe someone with more knowledge can maybe find an issue. I'm thinking, I'm missing something.

Thanks everyone.

I have very horrible power service at my property. I have a 7000 whisper watt diesel generator that I thought could use on my lathe.

The other night I plugged it in and the power light came on but the lathe would turn on and spin. So now I've been down tons of rabbit holes reading about start up power etc. I'm starting to think my generator won't work for this task. I'm still going to check a few things, like fuses, breakers and what not.

I'm not an electrician so lots of this is a 3rd language to me. I have a decent understanding but I'm wondering if wired the lathe for 120, if my generator would work then. It's currently wired for 220, I can't remember the size of the motor. For the generator 220 plug in is rated for 240 with 25amp. The 120 side is 120 with 25amp.

My question is would the start up draw be lower if I had it wired for 120?

I added some pictures so maybe someone with more knowledge can maybe find an issue. I'm thinking, I'm missing something.

Thanks everyone.