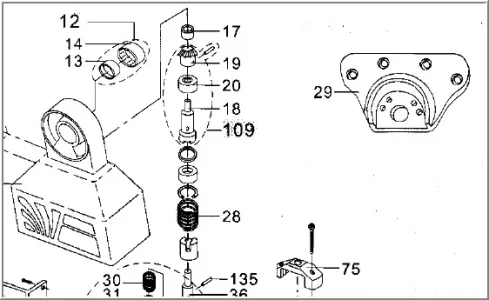

I see, that would take a bit of working for sure! The way it mounts is the end cap on the mill has 2 M6 theaded holes. The Power feed has like 8'ish holes that you use for mounting and they are located under behind the bevel gear, just like the picture you attached. This one has many mounting holes which I suppose are there to provide options for various mills..... So you slide the power unit on, fasten the 2 screws which secures the unit to the mill table / end cap and then the bevel gear slides over the leadscrew shaft, hand wheel goes back on and Bobs your uncle! It took a bit of tweaking but all in all it went on nicely! I am pleased with it! I actually used a piece of stainless to make the bushing between the leadscrew and the roller bearing in the power unit, since that it what I had handy in the right size. I found I got a fantastic finish in the bore by using a brazed carbide boring bar. Anyways, i'm off to bed. Will give this a full on test drive tomorrow. I have to cleanup all of the plasma cut edges on that AR400 plate that I cut so that's a perfect job to run the power feed for awhile.

Cheers!