I was reading comments on youtube where a viewer suggested a power feed could be added to the tailstock. The idea was to tie the tailstock to the carriage and engage the powerfeed. Leave the tailstock unlocked and then you could drill under power. Anybody doing this?

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Power drilling on lathe

- Thread starter Janger

- Start date

I have been considering something like this for use with the qctp one has an mt taper and the other just has the drill chuck mounted on a holder. I have watched a few videos seems interesting. I have not heard of attaching the tailstock in that way but sure it would be doable.

SHARS 6-12" AXA #53 Quick Change Morse Taper Tool Holder #3 MT 250-153 CNC P} | eBay

Find many great new & used options and get the best deals for SHARS 6-12" AXA #53 Quick Change Morse Taper Tool Holder #3 MT 250-153 CNC P} at the best online prices at eBay! Free shipping for many products!

www.ebay.ca

Aloris AXA-35 Dovetail Chuck Holder

www.ajaxtoolsupply.com

Here's how DSG did it. Unfortunately the only bit of tooling I don't have, but its such clever arrangement I keep threatening to make one. Clamp to the dovetail and a stop on the saddle ensures alignment. Never worry about spinning a drill in the tailstock taper.

Last edited:

Dirt Cheap Automatic Tailstock Feed for Your Metal Lathe

What a neat idea!!! https://www.homemadetools.net/forum/dirt-cheap-automatic-tailstock-feed-your-metal-lathe-83411?utm_source=newsletter&utm_medium=email&utm_campaign=01-18-21&utm_content=01-18-21-173473&fi=173473#post173473

canadianhobbymetalworkers.com

canadianhobbymetalworkers.com

historicalarms

Ultra Member

I did that exact thing a few years ago when I was thinking of drilling old rifle barrels & re-lining with new rifled liners as a side hustle.

I manufactured a hook system that would drag the tail stock down the ways under power of the carriage. basically it worked very well for the shallow start of a hole but after the first 6 inches of depth I didnt have the "feel" of the flutes filling up & binding like we do with a hand drill....and I was trying to drill 24-28 inches.

I thought it would work because of the fact I was just enlarging a hole that was already thru-drilled. I even tried very small drill increments of 1/16" but it still stuck & jammed without a feelable warning resulting in jammed & broken drill bits in in a couple very hard to replace antique gun barrels.

I guess my final report would read " doable for holes shorter than drill flutes. I think I have re-purposed that hook & latch system I fabricated into something else that was probably as useless LOL

I manufactured a hook system that would drag the tail stock down the ways under power of the carriage. basically it worked very well for the shallow start of a hole but after the first 6 inches of depth I didnt have the "feel" of the flutes filling up & binding like we do with a hand drill....and I was trying to drill 24-28 inches.

I thought it would work because of the fact I was just enlarging a hole that was already thru-drilled. I even tried very small drill increments of 1/16" but it still stuck & jammed without a feelable warning resulting in jammed & broken drill bits in in a couple very hard to replace antique gun barrels.

I guess my final report would read " doable for holes shorter than drill flutes. I think I have re-purposed that hook & latch system I fabricated into something else that was probably as useless LOL

I was reading comments on youtube where a viewer suggested a power feed could be added to the tailstock. The idea was to tie the tailstock to the carriage and engage the powerfeed. Leave the tailstock unlocked and then you could drill under power. Anybody doing this?

Unless your tailstock weighs a thousand pounds, I wouldn't trust it. Way too easy to have some very minor torque forces lifting up one edge of the tailstock. Even with a tiny bit of force on the snuggers, it will want to twist.

Edit - I've put drill rod in my tailstock and it takes VERY little torque to lift one side of the tailstock. I was testing the Clamps to see what kind of force it took to distort them. It was for a fellow member who was having trouble tying down his tailstock.

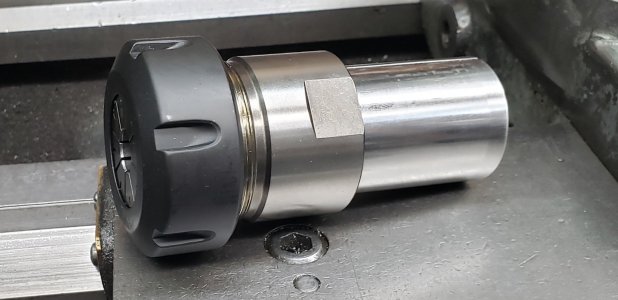

I have probably shown this before, but it is a great solution to a lot of drilling projects. The stroke is about 4". The quill is approximately 3 1/8" diameter and MT4. I bought the tailstock from a salvage yard for scrap price. It was from a large Japanese CNC lathe. It provides lots of "feel" for the drilling operation and chip ejection is so quick that it is no bother. Yes, the base is aluminum, but has served well for 20 years. The V ways are lined with "plastic steel" and have ceramic inlays in the epoxy to resist wear. I suspended the assembly between dead centers in the headstock and tailstock while the epoxy cured. Works for me.

Attachments

I was interested in a power feed drilling capability for the lathe a while ago, and looking at options. I read about this piggy back method, but decided against it. When I eventually got a Multifix QCTP, I ordered up the boring bar holder, and MT3 and MT4 adapter sleeves for it. So now I can spot drill, drill, chamfer, ream, so quickly its amazing. No more dragging the tailstock stock up and down the length of the bed. And now drill or ream at the suggested feeds. And even if you don't use it under power feed, you can still feel how its cutting. I bought one of those IGaging single DRO, and set Origin to the proper center of axis for drilling. Plus you can determine your exact depth of cut if you have a DRO, or a carriage stop/indicator. No more relying on the coarse hash marks on the tailstock spindle.I was reading comments on youtube where a viewer suggested a power feed could be added to the tailstock. The idea was to tie the tailstock to the carriage and engage the powerfeed. Leave the tailstock unlocked and then you could drill under power. Anybody doing this?

And I also have an ER40 collet chuck that I can put into the boring bar holder for doing other operations.

Though, I would not try to use a large drill right off the the bat. Spot drill, then I'll drill to depth with 1/4" drill bit (split point), then whatever size you want. I haven't gone larger than 1" and had no issues (after spot drilling and a couple size bits in between.)

Attachments

I have probably shown this before, but it is a great solution to a lot of drilling projects. The stroke is about 4". The quill is approximately 3 1/8" diameter and MT4. I bought the tailstock from a salvage yard for scrap price. It was from a large Japanese CNC lathe. It provides lots of "feel" for the drilling operation and chip ejection is so quick that it is no bother. Yes, the base is aluminum, but has served well for 20 years. The V ways are lined with "plastic steel" and have ceramic inlays in the epoxy to resist wear. I suspended the assembly between dead centers in the headstock and tailstock while the epoxy cured. Works for me.

Interesting post Ian but I don’t understand how it works. Can you please explain more?

Former Member

Guest

Power feeding can be done in various methods, just think out side the box. I hold the drill bit in my lathe chuck, hold the material in a jig on my cross slide. Engage feed...