This is all i have time for today, laundry, paperwork, grocery shopping are all calling my name......and according to my wife....."chippers" as well (potato chips)

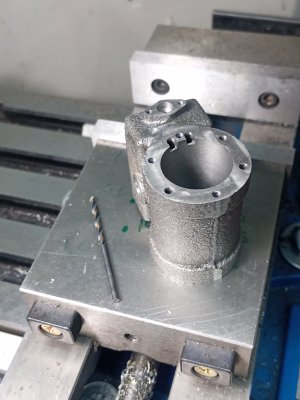

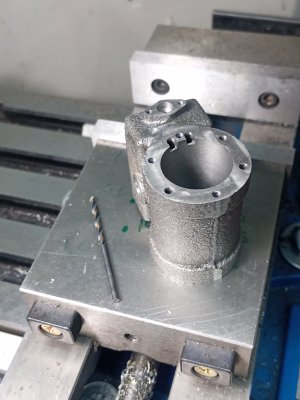

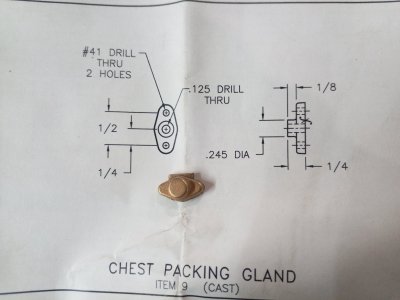

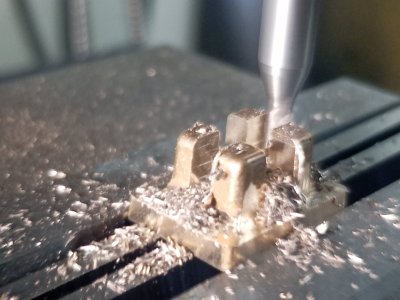

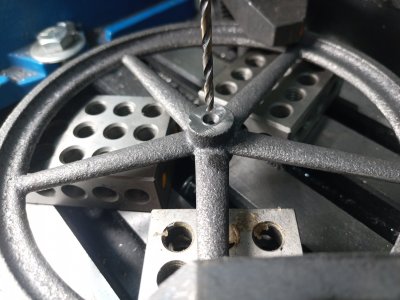

Casualty count for today : 1 - 7/64 drill bit...snapped as i broke through on the first steam hole into the steam inlet....switched to a cheaper, softer bit for the remainder (and used the called out 1/8...(there is a reason i used a 7/64, but thats another story). Problem solved, no more broken bits to try and remove.....although i was lucky enough to remove the broken bits without much trouble

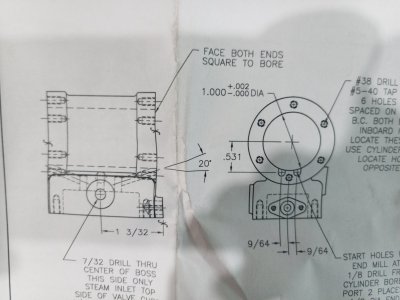

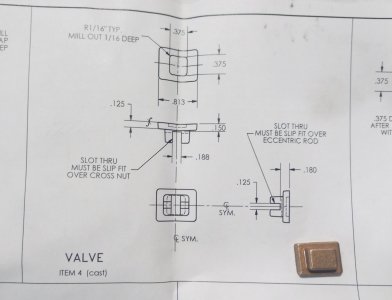

Locating the steam port holes seems to be a bit of a contentious item between the two youtubers.....BlondiHacks eyeballed it it happened to work out for her, Joe Pie goes on a great big tangent with some kind of fancy layout ball and a bunch of math (and lets be honest...is kind of a dick about it the whole time). Although this is probably the absolute most accurate way of locating those holes....I don't have a fancy layout ball...and would wager most hobbyists don't either...

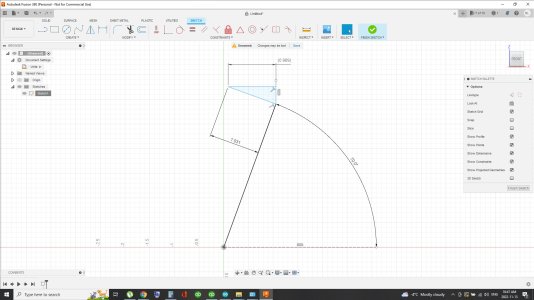

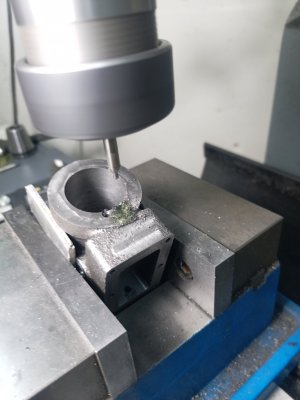

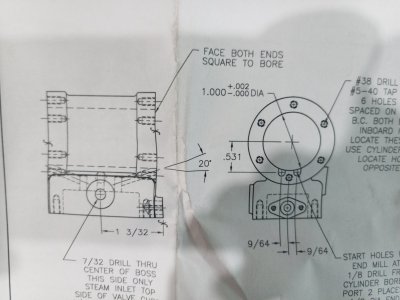

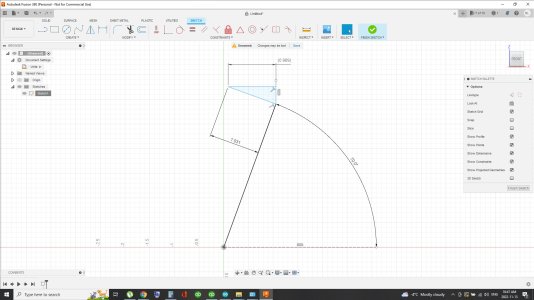

Not wanting to eyeball it, and being used to working with drawings that are missing the dimensions that would make life easier, it was not hard to see the missing right angle triangle created from the edge of the bore and the called out dimension (that makes the hypotenuse) . I used fusion 360 to do the math for me....because...it gave me a nice screen shot and....technology. Used an edge finder to find the edge of the bore (i know not perfect...but this is only half a piano), took off the radius of the finder, edge found both sides and halved (also not perfect)...then went off the dro for the remainder...i am off a few thou left to right....but all of the steam holes busted into the steam chest at a nice elevation, i would call that a success

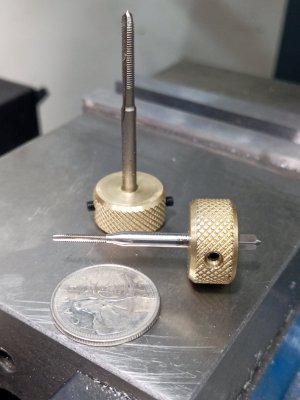

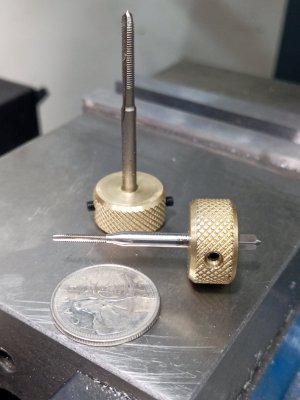

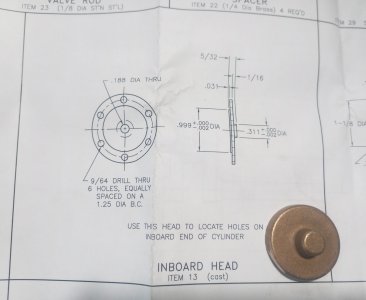

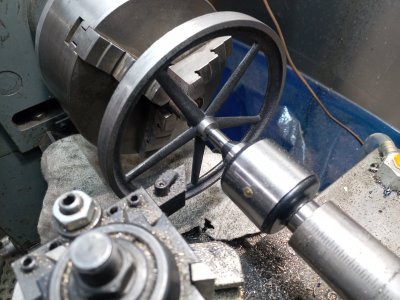

i also did not have any way of indicating the center of the bore for the head bolts....turned a chunk of scrap into a tight plug i could use to center everything up.....seemed to work well enough

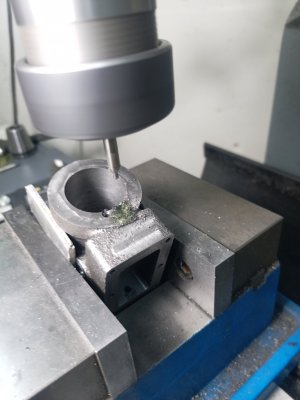

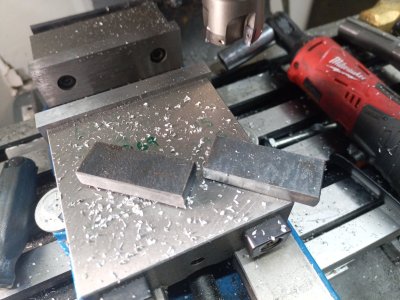

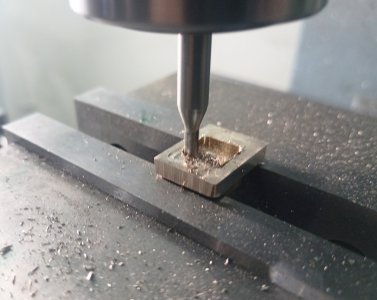

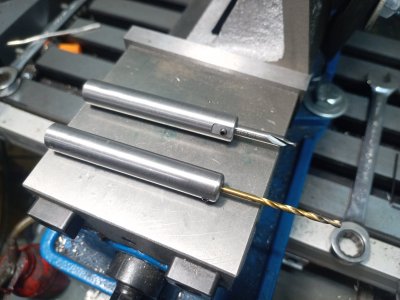

for the keen viewers, the reason im using an er32 collet chuck instead of r8 collets in the spindle....the collet chuck is very close in size to my drill chuck...i have a round column mill, this is a bit of a work around for not having to raise the head when going between a drill chuck and a short endmill

@PeterT no worry's, i dont mind tangents, its a forum after all, one thing leads to the next