I use fusion 360 on and off. I am competent with individual components but never really got the hang of their assemblies. The progress tree gets enormous fast. I originally learned CAD and CAM with solidworks but eventually lost access to it. With the cost of solidworks Cad/Cam being in excess of $20k I had to use something else. So fusion 360 it is.

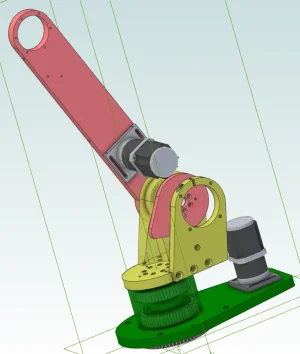

No real point in this post other than to maybe spark some conversation about Fusion 360. The part in the photo is a computer rendered image of three out of 4 crank case parts for a 18 cylinder double row radial engine. I was hoping for it to be a retirement project but with the cost of material it would be an expensive build.

No real point in this post other than to maybe spark some conversation about Fusion 360. The part in the photo is a computer rendered image of three out of 4 crank case parts for a 18 cylinder double row radial engine. I was hoping for it to be a retirement project but with the cost of material it would be an expensive build.