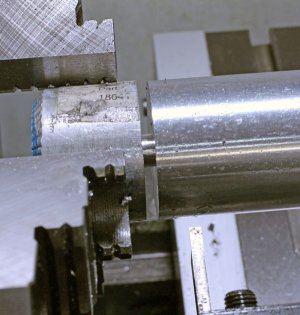

On todays episode of How Its Made - Aluminum Slinky's!

Just kidding, I had to part off some 1.5" diameter 6061 so put in my longer reach, 1/8" wide, T-blade. I had a particularly nice curl going so thought I'd share a picture. Hand fed, occasional drip of fluid (how it finally broke off because I paused a bit & interrupted the feed). I think its well over a meter unfolded.

Just kidding, I had to part off some 1.5" diameter 6061 so put in my longer reach, 1/8" wide, T-blade. I had a particularly nice curl going so thought I'd share a picture. Hand fed, occasional drip of fluid (how it finally broke off because I paused a bit & interrupted the feed). I think its well over a meter unfolded.