Tmate

Well-Known Member

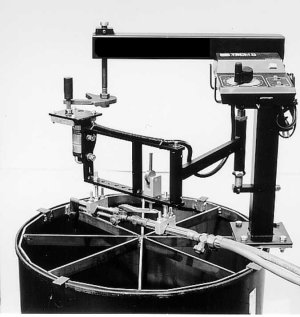

I fabricated this pantograph shape plasma cutting machine for duplicating steel brackets and other hardware. A variable speed knurled rotor moves around an overhead mounted template. The plasma torch tip, directly below, duplicates the shape in steel up to the thickness capacity of your plasma cutter. Shapes that would fit in a 16 inch circle, and straight lines up to 36" can be cut.

The frame of the machine is constructed of aluminum extrusions from the 8020 Company. The rest was fabricated from square tubing and cold roll steel bar. A model railroad transformer and small gear motor provide variable speeds in forward and reverse.

For those interested, I have made a free set of plans for building this unit available for download in pdf format at:

The frame of the machine is constructed of aluminum extrusions from the 8020 Company. The rest was fabricated from square tubing and cold roll steel bar. A model railroad transformer and small gear motor provide variable speeds in forward and reverse.

For those interested, I have made a free set of plans for building this unit available for download in pdf format at: