Tmate

Well-Known Member

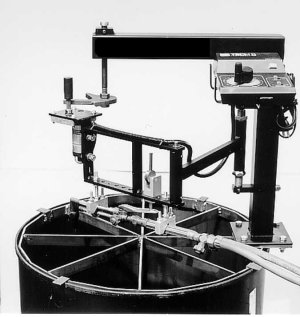

It isn't CNC, but it's a lot cheaper. A 1/4" thick steel template is supported on an overhead arm. The knurled magnetic rotor (a rotary file) rides around the edge of the template. The torch tip, below, is in direct line with the magnetic rotor, and duplicates the template shape. A slight allowance in the template size compensates for the radius of the rotor. Rotor is removed and replaced for interior parts of a template.

If only one or two pieces need to be cut, a wooden template can be used along with a 1/8" diameter rotor, which can be held against the template. With the small dia. rotor, no template size allowance is necessary.

Ist photo shows an oxy-acetylene setup, and the 2nd shows a plasma set-up. In both cases, a Grainger gearmotor is used in conjunction with a model railroad transformer. Magnetic tracer uses two iron boron magnets stacked on top of a rotary file.

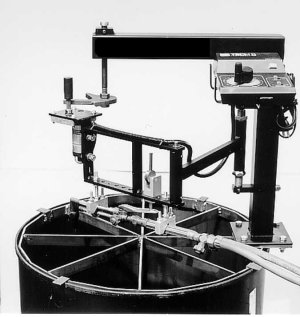

If only one or two pieces need to be cut, a wooden template can be used along with a 1/8" diameter rotor, which can be held against the template. With the small dia. rotor, no template size allowance is necessary.

Ist photo shows an oxy-acetylene setup, and the 2nd shows a plasma set-up. In both cases, a Grainger gearmotor is used in conjunction with a model railroad transformer. Magnetic tracer uses two iron boron magnets stacked on top of a rotary file.