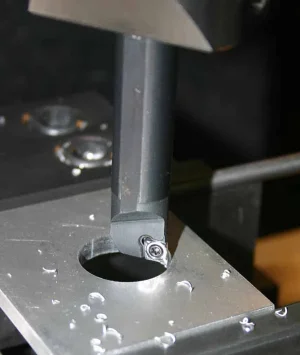

Another experimental project. My boring head has 1/2" holes. Thus far I've been using Borite HSS cutters. For a whopping 18$C including shipping, I bought this CCMT insert boring bar off AliExpress which is quite similar to what I use on the lathe. Its a 16mm nominal diameter shank which is next bigger metric size as they don't do inches. I lopped it off (sacrilege!) & turned down the end. My 3J chuck didn't quite grip it properly due to the opposing 2 flats orientation, 4J chuck is better. Seemed like reasonably tough mystery material but nothing onerous.

I thought about making the turn down stub length so the bar would be flush against the boring head underside. Aside from aesthetics, I couldn't see a good reason as they bottom out in the hole. The Borites just extend the 0.5" shank & neck down from there. These have even more meat than a stock but I'll give it a bit of chamfer just for looks. Besides, if the bar ever rotated it would scratch my shiny boring head

I considered leaving the stub round in order to rotate to different position & effectively tweak the rake angle. But now I think I'll replicate the flat to preserve the tool angle. I figure if it works in the lathe it should work in the boring head. Also with a flat, any set screw marks will occur there vs. marring the round & maybe make tool removal problematic since its not hardened.

Anyway, the general idea was maybe I could make some custom sizes for reasonable cost using inserts I already use. The same principle should work for large cutting radii with bar held horizontally, although I'd have to get left hand if I ran in same direction.

I thought about making the turn down stub length so the bar would be flush against the boring head underside. Aside from aesthetics, I couldn't see a good reason as they bottom out in the hole. The Borites just extend the 0.5" shank & neck down from there. These have even more meat than a stock but I'll give it a bit of chamfer just for looks. Besides, if the bar ever rotated it would scratch my shiny boring head

I considered leaving the stub round in order to rotate to different position & effectively tweak the rake angle. But now I think I'll replicate the flat to preserve the tool angle. I figure if it works in the lathe it should work in the boring head. Also with a flat, any set screw marks will occur there vs. marring the round & maybe make tool removal problematic since its not hardened.

Anyway, the general idea was maybe I could make some custom sizes for reasonable cost using inserts I already use. The same principle should work for large cutting radii with bar held horizontally, although I'd have to get left hand if I ran in same direction.