In the process of replacing the existing 24VDC brushed DC spindle on my cheap engraver.

Bought an Amazon <500 Watt> brushless Dc spindle motor, with 48 volt DC power supply and driver board.

The good - decent runout, seems to be reasonably made. Nameplate says 12,000 RPM, at no load at full speed my mechanical tach read 11,200 RPM, my optical tach read about the same.

The bad:

If this is 500 watt, I'm next in line to be Secretary General of the UN. No load @ 48VDC the controller pulls 1.55 Amp, so roughly 85 watt. Just because I'm a fussbudget, grabbed the Fluke meter and stuck it on the AC line to confirm. @ 120VAC, pulls 0.51 Amp. 61 watt. DC ammeter isn't filtered, so the reading bounced around a lot.

Meh. Probably more than adequate for use.

Maybe it would get to 500 watt under severe load, but it's intended to spin 1/8" mills or engraving bits at 12,000 RPM. Any cut aggressive enough to pull 500 watt is likely going to turn a 1/8" carbide end mill into dust. I'm using the cutters in the last photo.

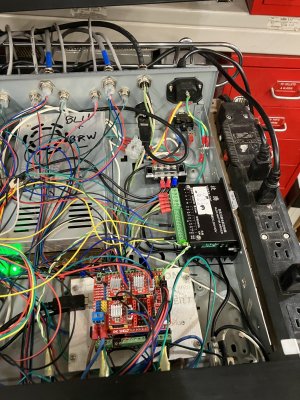

Next step is re-do all of the controls, install new stepper motors, make up a nice cabinet for all of the little boxes and cables, and replace the effing horrible factory wiring with real cables and plugs.

So far, my $200 3018 CNC toy engraver has cost me about $1k. Should have just bought the bigger better one from the get go, but what's the fun in that?

Bought an Amazon <500 Watt> brushless Dc spindle motor, with 48 volt DC power supply and driver board.

The good - decent runout, seems to be reasonably made. Nameplate says 12,000 RPM, at no load at full speed my mechanical tach read 11,200 RPM, my optical tach read about the same.

The bad:

If this is 500 watt, I'm next in line to be Secretary General of the UN. No load @ 48VDC the controller pulls 1.55 Amp, so roughly 85 watt. Just because I'm a fussbudget, grabbed the Fluke meter and stuck it on the AC line to confirm. @ 120VAC, pulls 0.51 Amp. 61 watt. DC ammeter isn't filtered, so the reading bounced around a lot.

Meh. Probably more than adequate for use.

Maybe it would get to 500 watt under severe load, but it's intended to spin 1/8" mills or engraving bits at 12,000 RPM. Any cut aggressive enough to pull 500 watt is likely going to turn a 1/8" carbide end mill into dust. I'm using the cutters in the last photo.

Next step is re-do all of the controls, install new stepper motors, make up a nice cabinet for all of the little boxes and cables, and replace the effing horrible factory wiring with real cables and plugs.

So far, my $200 3018 CNC toy engraver has cost me about $1k. Should have just bought the bigger better one from the get go, but what's the fun in that?