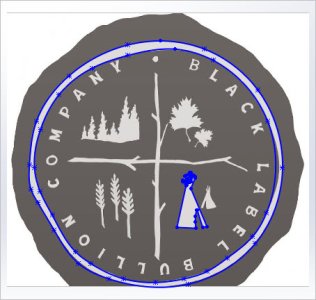

I'm just a hobbyist, not qualified on tool & die matters so just treat this as an idea. Maybe if the tool is confined to embossing on softer alloys like silver or copper, maybe you could get the designs laser etched so for example the black area etched 0.020" lower than the remaining white. If this was done in common O1 tool steel, its small enough that you could use ordinary torch to heat to red, quench in oil & temper in your oven to achieve typical tool steel RN hardness. What I don't know is if lasering can remove a specific thickness over an area like this, or if lasering has any heat effect on the part itself that ight adversely affect heat treating. But they could answer those questions.

Are you pressing these into the coin blanks with a press or something?