Building my press lead to looking for a Ram, finding one, and finding out it does not work..

I found this one on Kijiji,

and the guy said it was low on oil and he did not know how to fill it. I figured I could solve that and managed a pretty good price on it but it has become a project, of course......

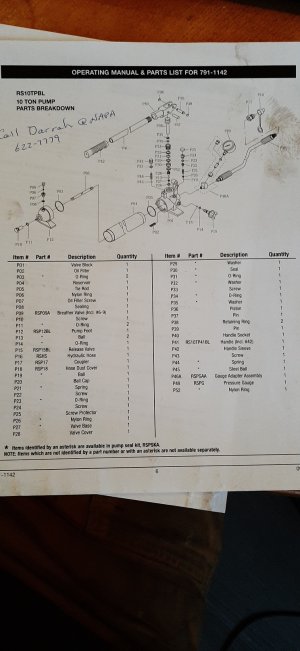

It does not develop pressure. The manual says to bleed air, put the ram on the floor and pump, release, pump, etc till air is out. Does not work, although sometimes, I could air gurgling back into reservoir when I opened the release valve. Today, I decided to just take it all apart and start from parts and the diagram and resassemble.

So, backing up a bit, yesterday....I removed P43 to find not one but 3 steel balls. They show one as P45. I found 2 smaller ones and one larger one. Not sure which one is the right size but I guess someone figured more balls is better.

I also found P26-P28 and P13 absent, although I don't see threads in the base for them so not sure if that is accurate. I hope to talk to NAPA tomorrow if unsuccessful today.

Now, today, after totally disassembling it all, in the diagram, you will see a little disc circled by yellow. This is about .250" in diameter and guessing, .030" thick. It was stuck (just by oil) to the inside of the base reservoir. It was basically floating around. It is either a part off of something else, simply a cutout from a plug cutter or a plug that is supposed to be somewhere....

Re Parts 29,31, and 32. P29 and 32 are listed as washers but are like piston rings, I mean, a scarf joint, and pry to get over the piston but made of nylon. They sandwich an oring between them. What do they do? They are smaller diameter than the oring so seem to not be affective but ....?

Oh, the green lines just point to two orifices in the body. All of the orifices seem to be interconnected so the function does rely on the springs and bearings. Perhaps when I put the big bearing back in, I should have used one of the two smaller ones. Having it apart, I can get a better idea of the valve seat size so will poke around.

So, this is today's project. If anyone has experience with these pumps, feel free to chime in.

I found this one on Kijiji,

and the guy said it was low on oil and he did not know how to fill it. I figured I could solve that and managed a pretty good price on it but it has become a project, of course......

It does not develop pressure. The manual says to bleed air, put the ram on the floor and pump, release, pump, etc till air is out. Does not work, although sometimes, I could air gurgling back into reservoir when I opened the release valve. Today, I decided to just take it all apart and start from parts and the diagram and resassemble.

So, backing up a bit, yesterday....I removed P43 to find not one but 3 steel balls. They show one as P45. I found 2 smaller ones and one larger one. Not sure which one is the right size but I guess someone figured more balls is better.

I also found P26-P28 and P13 absent, although I don't see threads in the base for them so not sure if that is accurate. I hope to talk to NAPA tomorrow if unsuccessful today.

Now, today, after totally disassembling it all, in the diagram, you will see a little disc circled by yellow. This is about .250" in diameter and guessing, .030" thick. It was stuck (just by oil) to the inside of the base reservoir. It was basically floating around. It is either a part off of something else, simply a cutout from a plug cutter or a plug that is supposed to be somewhere....

Re Parts 29,31, and 32. P29 and 32 are listed as washers but are like piston rings, I mean, a scarf joint, and pry to get over the piston but made of nylon. They sandwich an oring between them. What do they do? They are smaller diameter than the oring so seem to not be affective but ....?

Oh, the green lines just point to two orifices in the body. All of the orifices seem to be interconnected so the function does rely on the springs and bearings. Perhaps when I put the big bearing back in, I should have used one of the two smaller ones. Having it apart, I can get a better idea of the valve seat size so will poke around.

So, this is today's project. If anyone has experience with these pumps, feel free to chime in.