Great work, the con-rods look absolutely authentic. Seems to run just fine and considering the age and condition when you got it, that probably qualifies as a minor miracle!

When you say you 'reworked the valves', do you mean that you just had to adjust the timing or were there more problems?

Craig

Thanks for noticing the connecting rods. They're far from perfect, but they're the best I could do with my Burke #4 mill. I had a hard time getting the fluting right.

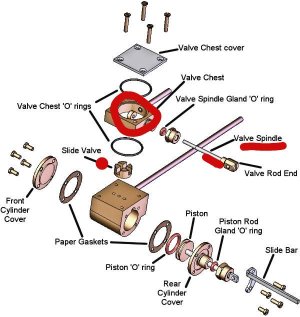

As for the valves, the original builder sort of stuck the spindles (not threaded) into the valves with bent nails, and this left no room for adjustment without removing the boiler and playing with the eccentrics to make a change, so I made new spindles from an old clock chime rod, threaded them, re-machined the valves to accept a threaded adjustment block (something like the little doughnut shown in the centre of the valve chest in the accompanying diagram, only rectangular), stuck it all together, adjusted valve travel with the new spindles, re-timed things, and it actually ran.

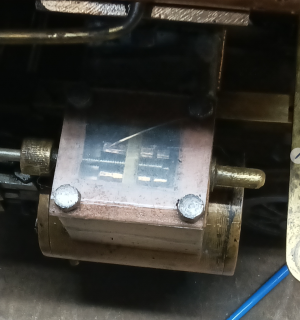

I have attached pictures of the making of the connecting rods, the old and new valve spindles, a new spindle installed, and a diagram to illustrate what I did with the valves. I trust that I make myself obscure....

By the way, the entire smokebox door assembly was missing, so I made a new one, too.

Now, on to the dome, the bell, the light, the cab, and more.