TorontoBuilder

Ultra Member

Now that my friend's woodworking shop is nearing completion I can get to a project I'm overdue to complete.

In the space constrained environment of my townhouse I need to use any available space for many different purposes. The dining room table is no longer an option for multiday projects.

So, I purchased a Flexispot E7 Plus 4-leg Standing Desk which is an adjustable height desk with four height presets. It can support (and lift) 540 pounds, but I'll not over tax it by loading up too much in the way of permanent fixtures.

The frame can accept a taop from 28 - 35" deep by 47 - 80" wide.

I have a 2" thick top of maple butcher top 27" x 57" that I can have for free, which I've drawn up a plan to add a perimeter to increase the size to fit the legs. I am not sold that it is wide enough for all my possible uses. But for now it helps plan what accessories etc I need.

I plan to do fussy assembly work and really need support for my forearms for this task, and extended typing sessions as well as for engraving so arm rests are such an essential item that I'll have a few sets of fully adjustable rests.

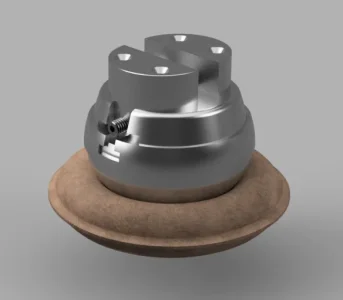

It is really annoying using an engraving ball vise that is elevated above the work surface for long periods of time. The same applies to engraving wood plates perched on top of sand bags. Really fancy work stations have wells so such accessories can sit below the main desk top. I need a large flat area, so I needed an alternative for the limited times I engrave or carve stone and wood. I think an add-on option will work well enough.

The empty voids on the sides are for tool drawers. I'll be making a vacuum slot/port that goes in the rear face to whisk away dust and chips for when I'm carving.

Another idea is to router a 1/2" deep oval in the top for different inserts... one with black leather and drafting table vinyl sides for fine work on old camera shutters, assembling small tools... where you don't want anything to get scratched or dropped parts to bounce away like crazy.

A soapstone insert that is heat and chemical resistant to silver solder over, smelt small volumes of silver and gold for jewelry making...

One granite insert for tool sharpening... with emery cloth affixed to surface.

In the space constrained environment of my townhouse I need to use any available space for many different purposes. The dining room table is no longer an option for multiday projects.

So, I purchased a Flexispot E7 Plus 4-leg Standing Desk which is an adjustable height desk with four height presets. It can support (and lift) 540 pounds, but I'll not over tax it by loading up too much in the way of permanent fixtures.

The frame can accept a taop from 28 - 35" deep by 47 - 80" wide.

I have a 2" thick top of maple butcher top 27" x 57" that I can have for free, which I've drawn up a plan to add a perimeter to increase the size to fit the legs. I am not sold that it is wide enough for all my possible uses. But for now it helps plan what accessories etc I need.

I plan to do fussy assembly work and really need support for my forearms for this task, and extended typing sessions as well as for engraving so arm rests are such an essential item that I'll have a few sets of fully adjustable rests.

It is really annoying using an engraving ball vise that is elevated above the work surface for long periods of time. The same applies to engraving wood plates perched on top of sand bags. Really fancy work stations have wells so such accessories can sit below the main desk top. I need a large flat area, so I needed an alternative for the limited times I engrave or carve stone and wood. I think an add-on option will work well enough.

The empty voids on the sides are for tool drawers. I'll be making a vacuum slot/port that goes in the rear face to whisk away dust and chips for when I'm carving.

Another idea is to router a 1/2" deep oval in the top for different inserts... one with black leather and drafting table vinyl sides for fine work on old camera shutters, assembling small tools... where you don't want anything to get scratched or dropped parts to bounce away like crazy.

A soapstone insert that is heat and chemical resistant to silver solder over, smelt small volumes of silver and gold for jewelry making...

One granite insert for tool sharpening... with emery cloth affixed to surface.