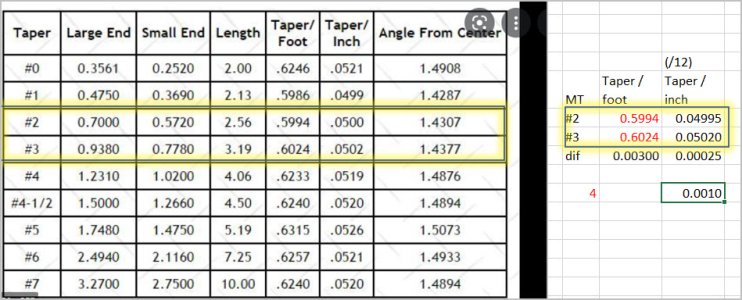

I need to make a MT2 taper and my taper attachment is already setup for MT3 (or so I think the increments on the attachment are pretty course).

According to this chart https://littlemachineshop.com/reference/tapers.php there isn't a heck of a lot of difference between MT3 and MT2 apart from the diameters and length of the taper.

Will my current setup suffice for making a MT2 taper?

Thanks,

Craig

According to this chart https://littlemachineshop.com/reference/tapers.php there isn't a heck of a lot of difference between MT3 and MT2 apart from the diameters and length of the taper.

Will my current setup suffice for making a MT2 taper?

Thanks,

Craig