No worries. I have 2 part reversible jaws on some chucks as well. They are in pretty good shape but it can't stop my mind to wandering for 'one day' when its required or I inherit something that needs remediation. I had the same general idea as you have shown (if I understand it correctly) & I think I've seen variations to the theme elsewhere. But there may still be some devil in the details.

If the dummy pin extension has any kind of clearance to the jaw hole counterbore, which it pretty much has to have to get in the hole, then loading the protruding pin segment against the ring is only bending the dummy pin independent of the jaw. The pin is anchored at the base of mount hole, so its basically deflecting like a cantilever beam until/if it ever makes contact with the jaw. That is not the same loading mode as a stop or notch or pin located at the upper jaw surface face and very near the jaw grip surface. I was thinking of some kind of tapered cone extension that makes tangent contact with the counterbore lip. But that would only work on the outer hole, not the inner hole where its most desired. Even so, looks dodgy & complicated to me.

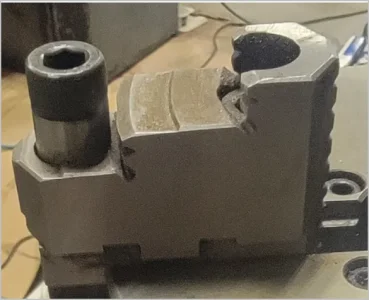

I think the Crispin clamps are a better solution. Easy to make. They don't involve drilling pin holes into the jaws (Stefan) or relief notches (Renzetti). Not to say these methods are bad, just a few pay grades above my tooling & experience. I don't think my quick & dirty hardness testing was definitive but my jaws are pretty damn hard, so it cooled my jets about drilling with carbide.

View attachment 37593View attachment 37594View attachment 37595