SparWeb

Active Member

Hello,

I've been enjoying my CNC router table since getting it several months ago. The holidays have given me time to try some more ambitious projects, and get tighter tolerances on parts. I knew this is when limitations or problems would show up, but no disasters so far.

canadianhobbymetalworkers.com

It's a CNC gantry router (42" x 30") with stepper motors. The gantry moves on belt-driven rack and-pinion, pretty typical.

canadianhobbymetalworkers.com

It's a CNC gantry router (42" x 30") with stepper motors. The gantry moves on belt-driven rack and-pinion, pretty typical.

I have run into a little mystery and I'd like to run it by the wise members here, before I change a setting I don't understand.

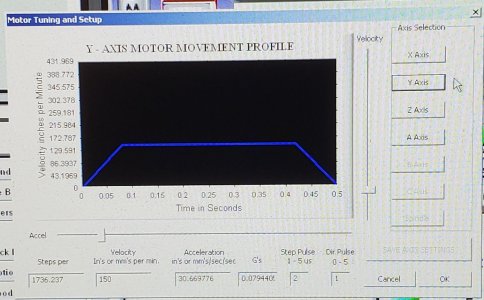

I set out to correct a scaling error, and I seem to have found a racking error at the same time. No big surprise, but as I investigated further, I found that the two motors driving the Y-axis have different parameters set. These 2 stepper motors are slaved together and I would assume that they should operate identically. Instead I find that only the velocity settings are the same. They are set to different accelerations. I don't understand why this would be.

Master:

Steps 1736.237

Velocity: 150 in/min

Accel: 30.669776 in/sec/sec

G's: 0.07944

Step Pulse: 2 microsec

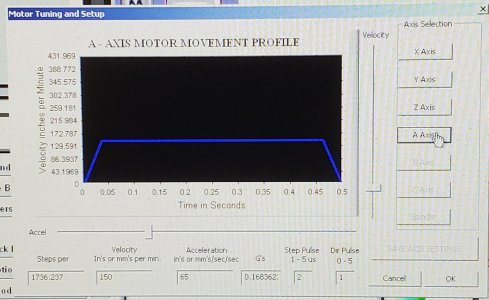

Slave:

Steps 1736.237

Velocity: 150 in/min

Accel: 65.0 in/sec/sec

G's: 0.16836

Step Pulse: 2 microsec

Should I change them to match, or is there a reason for the two settings to be different?

I've been enjoying my CNC router table since getting it several months ago. The holidays have given me time to try some more ambitious projects, and get tighter tolerances on parts. I knew this is when limitations or problems would show up, but no disasters so far.

Anybody still using Mach3?

I bought a CNC router! It's old! No it's not that bad, but it's a DIY project that the guy has picked at for almost 20 years. Still works, and tonight I have cut wood by jogging the cutter, just trying it out. Learning as I go. The CNC software is installed on a geriatric Windows XP computer...

canadianhobbymetalworkers.com

canadianhobbymetalworkers.com

I have run into a little mystery and I'd like to run it by the wise members here, before I change a setting I don't understand.

I set out to correct a scaling error, and I seem to have found a racking error at the same time. No big surprise, but as I investigated further, I found that the two motors driving the Y-axis have different parameters set. These 2 stepper motors are slaved together and I would assume that they should operate identically. Instead I find that only the velocity settings are the same. They are set to different accelerations. I don't understand why this would be.

Master:

Steps 1736.237

Velocity: 150 in/min

Accel: 30.669776 in/sec/sec

G's: 0.07944

Step Pulse: 2 microsec

Slave:

Steps 1736.237

Velocity: 150 in/min

Accel: 65.0 in/sec/sec

G's: 0.16836

Step Pulse: 2 microsec

Should I change them to match, or is there a reason for the two settings to be different?