Bruce Rossiter

Active Member

Hopefully I can work my way through this post. I purchased my bead roller from Princess Auto and immediately realized that it needed a few modifications.

The first change needed was to build a stand to hold the bead roller and all the dies.

The second change was to drill and tap the bracket and upper bearing support in order to spring load the upper support and shaft. This will return the upper shaft when the depth adjustment is released.

The third change was to replace the tension bolt with a handle (red) eliminating the use of a wrench. It just made it more convenient and quicker to adjust the tension.

The fourth change was to reinforce the back of the main frame to stop the flexing when pressure is applied. The reinforcement was made with 1 1/4" square tubing.

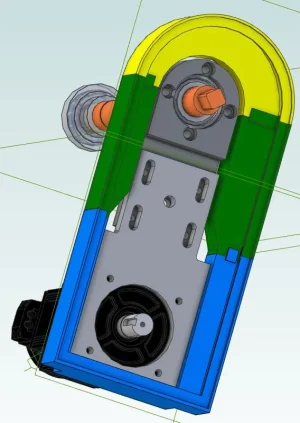

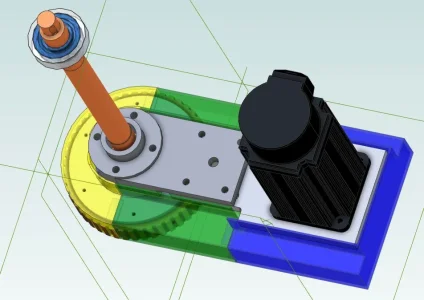

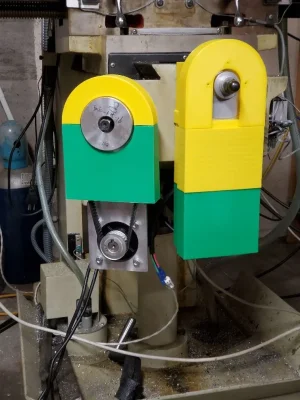

Finally I added a foot operated drive motor to enable me to use 2 hands to guide the metal through the bead roller.

I guess you could say that this was an exercise in changing a cheap bead roller into a useful piece of equipment.

The first change needed was to build a stand to hold the bead roller and all the dies.

The second change was to drill and tap the bracket and upper bearing support in order to spring load the upper support and shaft. This will return the upper shaft when the depth adjustment is released.

The third change was to replace the tension bolt with a handle (red) eliminating the use of a wrench. It just made it more convenient and quicker to adjust the tension.

The fourth change was to reinforce the back of the main frame to stop the flexing when pressure is applied. The reinforcement was made with 1 1/4" square tubing.

Finally I added a foot operated drive motor to enable me to use 2 hands to guide the metal through the bead roller.

I guess you could say that this was an exercise in changing a cheap bead roller into a useful piece of equipment.