Now that I've been poking my nose in here more often I guess I better post something what I've actually accomplished in the shop recently.

Just finished a model traction engine of the "Minnie" design in 1" size (i.e., 1" to the foot). It is a freelance design of no particular actual engine but does replicate most if not all features an actual engine would have.

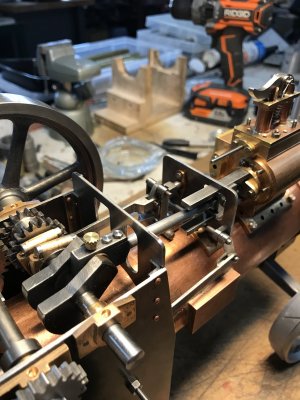

Here is a photo before and a couple after paint:

It was a great project to build. Lots of variety with all the different materials and parts to fabricate.

Just finished a model traction engine of the "Minnie" design in 1" size (i.e., 1" to the foot). It is a freelance design of no particular actual engine but does replicate most if not all features an actual engine would have.

Here is a photo before and a couple after paint:

It was a great project to build. Lots of variety with all the different materials and parts to fabricate.