Recent projects have gotten me to use the milling vise a little more. I noticed that the moving jaw lifted when I tightened it up. Tapping down the material did not matter. Inserting a soft piece of rod on it did not matter. I could not get the back parallel to be tight. Very frustrating. And the numbers on the dial are hard to read. So, apart it came!! I have not taken one apart before so what is new for me might be familiar to you.

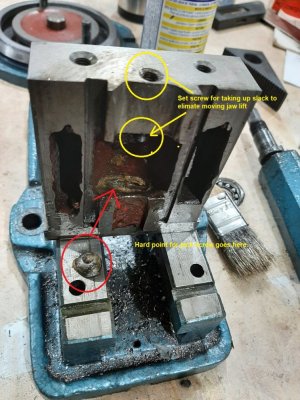

After taking it apart, I found the screw adjustment to take up the slack, and the hard point it fixes on. Now things made sense. I figured there must be something but wanted to see how it worked before just turning screws. But it was interesting to see how it was all put together. Also, how rough the casting is! When I googled the problem, I seemed to find a lot of great videos and documentation on rebuilding KURT vices but nothing on these little China imports. No one cares?

I took some measurements on the bearing, in case I can find a replacement. Not that it seems bad, but it just looks like crap. Not sure if it is worth it to replace it or not. I almost think a brass bushing would be better but I probably will not use it enough to wear it out. Having said that, I think it is better after cleaning and greasing so the bearing will probably remain.

Bottom line, after cleaning it up, filing the rough edges, lubing and adjustments, the difference is night and day! Tightening up the vise on a workpiece often leaves pressure on both parallels, or if the rear is a little loose, a light tap snugs it up. It ain't no KURT but I feel better about using it and have much more satisfaction (ie less frustration) with my setups. So if you find your import vise frustrating, check it out! Time well spent...

But now I need to find out a way to improve those markings. I cleaned the dial, then blued it, thinking that stuff seems pretty resistant to being rubbed off. I also wanted to see if the indentations were enough to hold a colour but nope! So I need to find a way to deepen the grooves for each one and then paint. A small dremel? Is there a tool for this? Mount the base at an angle and do in the mill? The dial sits at an angle of about 30 degrees from vertical. Any suggestions? I think that doing it free hand will look poor so I think a setup of some sort, with the right tool, is necessary.

Cheers,

Shawno

After taking it apart, I found the screw adjustment to take up the slack, and the hard point it fixes on. Now things made sense. I figured there must be something but wanted to see how it worked before just turning screws. But it was interesting to see how it was all put together. Also, how rough the casting is! When I googled the problem, I seemed to find a lot of great videos and documentation on rebuilding KURT vices but nothing on these little China imports. No one cares?

I took some measurements on the bearing, in case I can find a replacement. Not that it seems bad, but it just looks like crap. Not sure if it is worth it to replace it or not. I almost think a brass bushing would be better but I probably will not use it enough to wear it out. Having said that, I think it is better after cleaning and greasing so the bearing will probably remain.

Bottom line, after cleaning it up, filing the rough edges, lubing and adjustments, the difference is night and day! Tightening up the vise on a workpiece often leaves pressure on both parallels, or if the rear is a little loose, a light tap snugs it up. It ain't no KURT but I feel better about using it and have much more satisfaction (ie less frustration) with my setups. So if you find your import vise frustrating, check it out! Time well spent...

But now I need to find out a way to improve those markings. I cleaned the dial, then blued it, thinking that stuff seems pretty resistant to being rubbed off. I also wanted to see if the indentations were enough to hold a colour but nope! So I need to find a way to deepen the grooves for each one and then paint. A small dremel? Is there a tool for this? Mount the base at an angle and do in the mill? The dial sits at an angle of about 30 degrees from vertical. Any suggestions? I think that doing it free hand will look poor so I think a setup of some sort, with the right tool, is necessary.

Cheers,

Shawno

Attachments

Last edited: