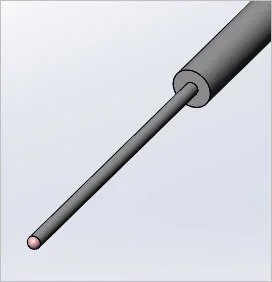

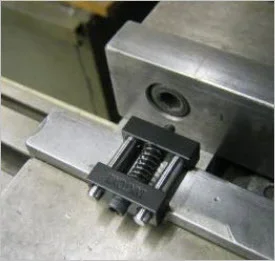

I’ve been working on a mill vise stop. After looking at various types online I decided to make a fairly simple one. There are a number of firsts here for me. The Cnc control on my mill made the drilling for the shaft and the holes for knob really simple and accurate. Other than one gcode fumble the holes lined up really well. I also found the machine located the very top of the round stock easily. I tested with pressing down on a ruler lying on the stock with the drill bit and it was level with no fiddling.

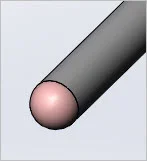

I also used @PeterT spreadsheet to calculate nominal diameter shaft diameter to nicely knurl the knob. Thanks Peter! That’s my first knurl and I used the busy bee scissor type tool. Turned out pretty good I thought. A good little project lots of fun.

I also used @PeterT spreadsheet to calculate nominal diameter shaft diameter to nicely knurl the knob. Thanks Peter! That’s my first knurl and I used the busy bee scissor type tool. Turned out pretty good I thought. A good little project lots of fun.