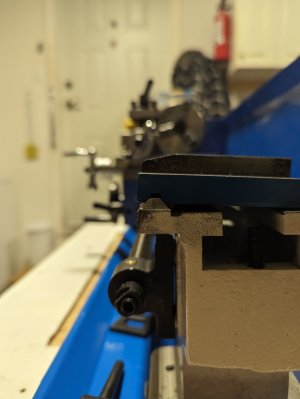

Hey folks. I was given a mini lathe 7x12 by a friend's family and it's mint, except for the base of the tailstock. The grove is too small for the rail so I will have to mill in on my mini mill. Any suggestions beside getting a better lathe. (Baby steps). Zoom in on the pic to see.

Cheers & Thx

Cheers & Thx