Grizzly Adams

Active Member

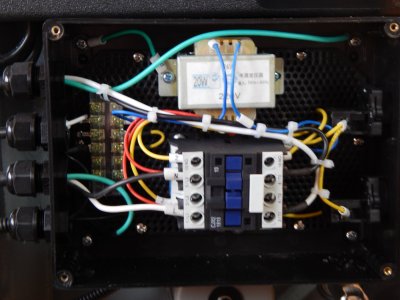

So, the mill I bought is a King model 31, which I also see described as a PDM 30. As it came, it's set up to run on 220 v, but the manual apparently allows for conversion to 110v and there are instructions in the motor junction box, which I have followed. It ain't working. Am I missing something ?