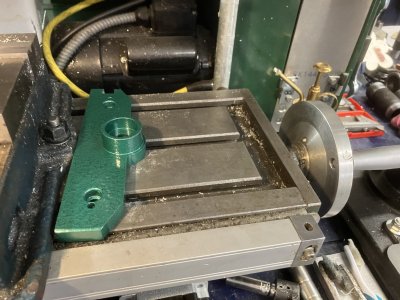

Question regarding adding a power feed to a smallish bench mill. I have a BB CT129 (same as a Grizzly G0704). I measured the operating torque under a reasonable cutting load, and I need about 7Nm / 60 in-lb worst case.

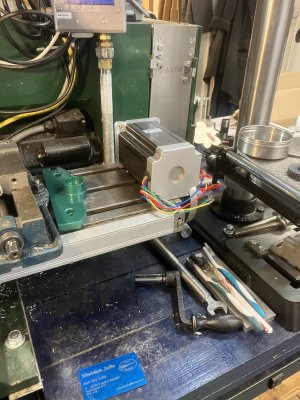

I have a nice new NEMA 34 stepper motor, puts out 12Nm / 100 in-lb locked rotor, so lots of safety factor.

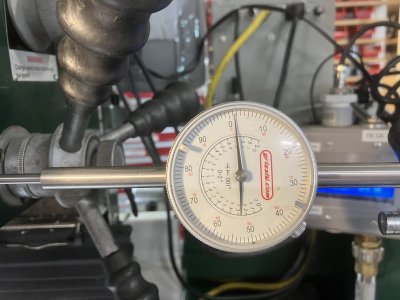

My concern is weight - the motor weighs about 5 kg. Should I be concerned about hanging this much weight off the end of the table? I know that if I run the table to the end of stroke and then really lean on the table, my dial indicator will show maybe 0.003” deflection.

Or just add some weight to the opposite end of the table to compensate for the motor weight?

I have a nice new NEMA 34 stepper motor, puts out 12Nm / 100 in-lb locked rotor, so lots of safety factor.

My concern is weight - the motor weighs about 5 kg. Should I be concerned about hanging this much weight off the end of the table? I know that if I run the table to the end of stroke and then really lean on the table, my dial indicator will show maybe 0.003” deflection.

Or just add some weight to the opposite end of the table to compensate for the motor weight?