I was wondering how a metric threading dial works and ran across a really cool tip on cutting metric threads with an imperial lathe.

I've always thought you had to leave the half nut engaged while you start, cut thread, stop, retract cross slide, reverse, stop, return cross slide, advance threading tool on compound, start, and repeat. But this method significantly increases the risk of a crash when threading to a shoulder.

Turns out that it isn't necessary after all.

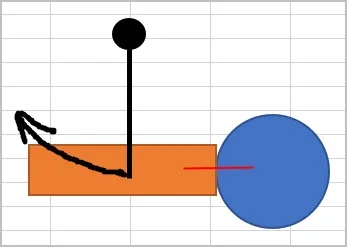

The trick is to cut the thread as usual, disengage the half nut as usual, then stop the lathe, then reverse the lathe and engage the half nut when the threading dial gets to whatever you had it on for the first pass.

Essentially, this is like never releasing the half nut - except you do. You just use reverse to get back to exactly where you were when you disengaged it.

I tried it myself today and it works like a charm.

Maybe some of you already knew that. But I didn't and I love it. I'll never be reluctant to cut metric threads again.

I've always thought you had to leave the half nut engaged while you start, cut thread, stop, retract cross slide, reverse, stop, return cross slide, advance threading tool on compound, start, and repeat. But this method significantly increases the risk of a crash when threading to a shoulder.

Turns out that it isn't necessary after all.

The trick is to cut the thread as usual, disengage the half nut as usual, then stop the lathe, then reverse the lathe and engage the half nut when the threading dial gets to whatever you had it on for the first pass.

Essentially, this is like never releasing the half nut - except you do. You just use reverse to get back to exactly where you were when you disengaged it.

I tried it myself today and it works like a charm.

Maybe some of you already knew that. But I didn't and I love it. I'll never be reluctant to cut metric threads again.