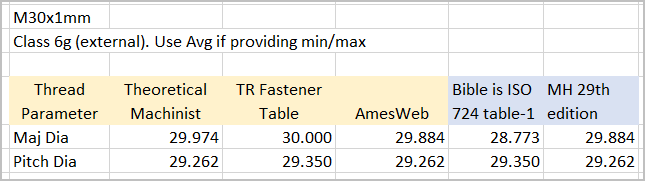

I thought I made a prior typo error, but now that I input the exact same (custom) metric thread into 3 different web calculators I've bookmarked, I see they are giving me slightly different answers.

Has anyone had this same issue? For example M30 x 1 6g (external) just comparing major diameter & pitch diameter to spot check. If the calculator provides a min/max I averaged the two just for spot check

theoreticalmachinist.com

theoreticalmachinist.com

Has anyone had this same issue? For example M30 x 1 6g (external) just comparing major diameter & pitch diameter to spot check. If the calculator provides a min/max I averaged the two just for spot check

Metric screw thread: M Profile calculator

Metric Thread Calculator

Calculate external and internal metric thread dimensions including major diameter, minor diameter, pitch diameter and thread tolerance according to ISO 724 and ISO 965 standards.

amesweb.info