Cryoine

Active Member

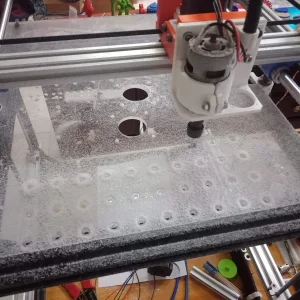

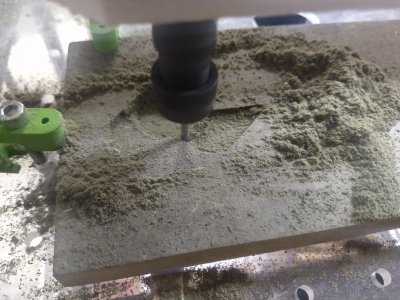

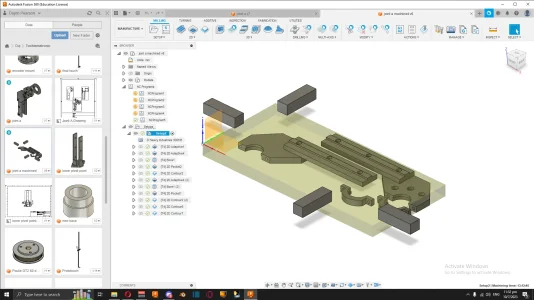

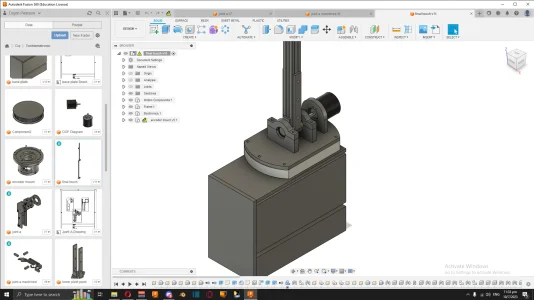

nothing really special just messing about with fusion 360 CAM, actually running the programs that I create is a nice thing, esp when I get to see how the machine behaves under load vs how it behaves in software. The CNC mill is a PCB mill that i designed in Fusion lol and now its come back full circle

the project that I am testing this all on is my "touchie-matronic" a coordinate measuring machine (should be 5 degrees of freedom) that I am working on to possibly submit as my final project for my mechanical degree (if I don't use the mill as that project)

Touchimatronic

this is joint A the joint that will hold one of the 5 encoders for the machine, it is the one that i picked for testing on the mill

joint A 3d printed in CPE filament, co-polyester its a very good prototyping filament but cannot be exposed to heat or the sun, it prints with a nice surface finish as well

MDF that a friend of mine gave me, it machines on the mill very nicely, but exposed some weaknesses of the mill itself, since it was designed primarily to work with PCB material it was not designed to be particularly rigid but the need for machining harder materials has arises so I will be redesigning some of the elements to take the increased forces

the project that I am testing this all on is my "touchie-matronic" a coordinate measuring machine (should be 5 degrees of freedom) that I am working on to possibly submit as my final project for my mechanical degree (if I don't use the mill as that project)

Touchimatronic

this is joint A the joint that will hold one of the 5 encoders for the machine, it is the one that i picked for testing on the mill

joint A 3d printed in CPE filament, co-polyester its a very good prototyping filament but cannot be exposed to heat or the sun, it prints with a nice surface finish as well

MDF that a friend of mine gave me, it machines on the mill very nicely, but exposed some weaknesses of the mill itself, since it was designed primarily to work with PCB material it was not designed to be particularly rigid but the need for machining harder materials has arises so I will be redesigning some of the elements to take the increased forces

Attachments

-

image_2023-07-10_233014600.webp266.8 KB · Views: 6

image_2023-07-10_233014600.webp266.8 KB · Views: 6 -

image_2023-07-10_233025622.webp164.2 KB · Views: 5

image_2023-07-10_233025622.webp164.2 KB · Views: 5 -

image_2023-07-10_233044694.webp143.3 KB · Views: 5

image_2023-07-10_233044694.webp143.3 KB · Views: 5 -

IMG_20230706_135842107.jpg441.6 KB · Views: 7

IMG_20230706_135842107.jpg441.6 KB · Views: 7 -

IMG_20230706_151645683.jpg344 KB · Views: 7

IMG_20230706_151645683.jpg344 KB · Views: 7 -

IMG_20230706_154027219.jpg275.2 KB · Views: 7

IMG_20230706_154027219.jpg275.2 KB · Views: 7 -

IMG_20230706_154034560.jpg266.7 KB · Views: 6

IMG_20230706_154034560.jpg266.7 KB · Views: 6 -

IMG_20230710_141711011.jpg398.4 KB · Views: 8

IMG_20230710_141711011.jpg398.4 KB · Views: 8 -

IMG_20230710_141716359.jpg342.3 KB · Views: 8

IMG_20230710_141716359.jpg342.3 KB · Views: 8 -

image_2023-07-10_233257345.webp114.4 KB · Views: 8

image_2023-07-10_233257345.webp114.4 KB · Views: 8 -

image_2023-07-10_233331395.webp97.1 KB · Views: 8

image_2023-07-10_233331395.webp97.1 KB · Views: 8