I was trying to see what kind of applications Meehanite was used for with the thought that maybe you could find, oh I dunno, a big muther caterpillar crankshaft at a wrecker & corner the market for model engine supply Haha. Probably about the same odds as tripping on a gold ingot. Amazingly there are many Meehanite sub-varietals I wasn't aware of. Not that I knew much about it anyways.

Re model engine hard chroming, apparently Jim was 'the guy' until he passed couple years back now. I'm pretty sure he did Nelson's & possibly Jetts liners. (I used to pylon race so I knew guys who knew guys...). My buddies got a shop tour of the skunkworks which made me insane with jealousy. This post was one of his last & shows some of the chroming specialization involved. Apparently even when the chrome goes down right, the real fun begins grinding & then the experts divide again on lapping.

.90 cu in, 30,000 RPM, 7.2 HP custom built nitro engine

www.modelenginemaker.com

Not directly related unless you hit a dead end and/or just enjoy the engine era.

An Italian (5cc) Beauty

www.modelenginemaker.com

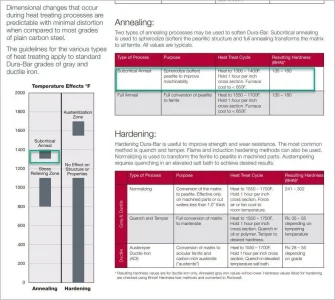

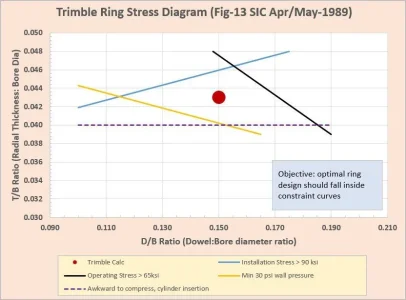

My radial. The liners are class-40 gray iron, lapped to within 0.0001". Its 4-stroke so uses (commercial) rings. Which, I concluded is painfully more work. Making the CI rings isn't any more challenging than other bits, but I didn't have the proper heat treat oven gear to heat-set the rings at specific temp + soak period. But I will overcome that issue on the next build!