My 5-cylinder radial is on the proverbial home stretch. More recently finalizing the test stand, glow ignition system, fuel system & seemingly endless remaining To-do list. Don't ask me when prop flip day is - 'soon', the goal posts keep receding. LOL

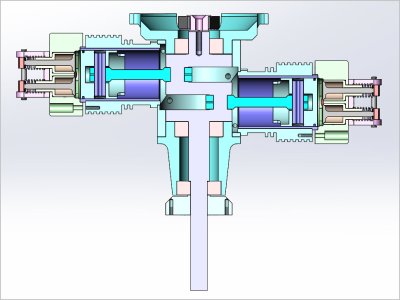

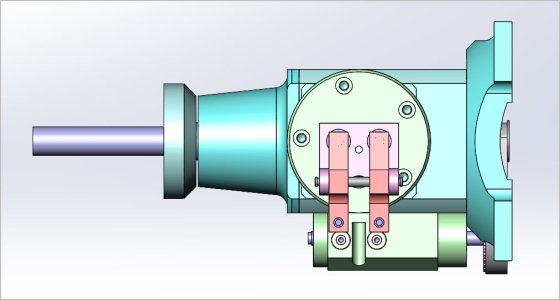

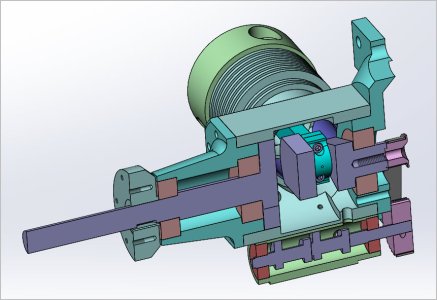

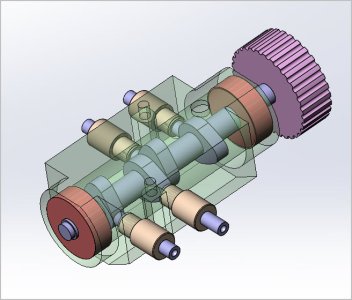

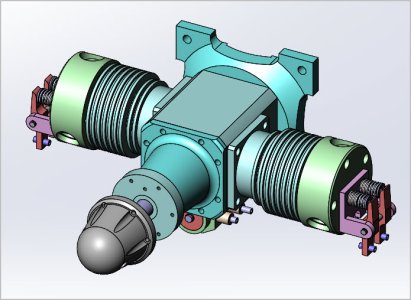

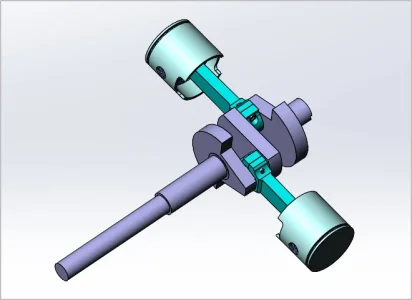

Anyway, I've also been thinking forward about the next project. There are lots of engines that interest me, but a more logical approach would be something simpler to prove out anticipated issues that would be encountered. I've had these twin plans for a while, its a 60cc horizontally opposed layout, 30cc per cylinder. Not very pretty or scale like, but maybe a good candidate for stated reasons. I finished the CAD work to get a feel for overall design. Its a one piece 2-throw crankshaft which is the bane of model engineers whittling out of solid, getting all the bearing surfaces perfect & mostly minimizing post machining stress relief distortion. Same comment for camshaft plus the added fun of hardening. Camshaft timing is via belt system which is mechanically simpler & maybe advantageous for adjustments. This time I want to make my own piston rings which is kind of a sub-adventure in itself due to heat setting fixtures involved. I'd like to pursue spark ignition / gasoline vs glow plugs / methanol. Spark plus are available in same (1/4-32) thread/size format as glow plugs, that's the easy part. Thereafter kind of a domino effect of related issues - the spark ignition system (buy & fly solid state module vs homebrew-ish distributer, coil etc.). Gasoline can dictate different compression ratio, carb sizing, lubrication, cam/ignition timing. I don't care for the thread-in style of intake/exhaust manifold coupler/tubes on my radial & this engine has the same. I'd like to substitute with bolt-on assembly which sounds straightforward but actually brings up new issues. But this head is bigger & the ports are more spread out, so a good candidate on that basis. Most engines like this get away with oil pre-mix, but real engines have oil pumps. The rear end is relatively open & simple so might be amenable to pump. I'll give this project some more noodling, but it checks quite a few boxes for now.

https://www.cad-modelltechnik-jung.de/construction-plans-model-engines.html

Anyway, I've also been thinking forward about the next project. There are lots of engines that interest me, but a more logical approach would be something simpler to prove out anticipated issues that would be encountered. I've had these twin plans for a while, its a 60cc horizontally opposed layout, 30cc per cylinder. Not very pretty or scale like, but maybe a good candidate for stated reasons. I finished the CAD work to get a feel for overall design. Its a one piece 2-throw crankshaft which is the bane of model engineers whittling out of solid, getting all the bearing surfaces perfect & mostly minimizing post machining stress relief distortion. Same comment for camshaft plus the added fun of hardening. Camshaft timing is via belt system which is mechanically simpler & maybe advantageous for adjustments. This time I want to make my own piston rings which is kind of a sub-adventure in itself due to heat setting fixtures involved. I'd like to pursue spark ignition / gasoline vs glow plugs / methanol. Spark plus are available in same (1/4-32) thread/size format as glow plugs, that's the easy part. Thereafter kind of a domino effect of related issues - the spark ignition system (buy & fly solid state module vs homebrew-ish distributer, coil etc.). Gasoline can dictate different compression ratio, carb sizing, lubrication, cam/ignition timing. I don't care for the thread-in style of intake/exhaust manifold coupler/tubes on my radial & this engine has the same. I'd like to substitute with bolt-on assembly which sounds straightforward but actually brings up new issues. But this head is bigger & the ports are more spread out, so a good candidate on that basis. Most engines like this get away with oil pre-mix, but real engines have oil pumps. The rear end is relatively open & simple so might be amenable to pump. I'll give this project some more noodling, but it checks quite a few boxes for now.

https://www.cad-modelltechnik-jung.de/construction-plans-model-engines.html

Attachments

-

SNAG-2022-12-22 2.01.07 PM.jpg60.2 KB · Views: 6

SNAG-2022-12-22 2.01.07 PM.jpg60.2 KB · Views: 6 -

SNAG-2022-12-22 2.01.48 PM.jpg44.4 KB · Views: 6

SNAG-2022-12-22 2.01.48 PM.jpg44.4 KB · Views: 6 -

SNAG-2022-12-22 2.02.49 PM.jpg65.8 KB · Views: 4

SNAG-2022-12-22 2.02.49 PM.jpg65.8 KB · Views: 4 -

SNAG-2022-12-22 2.09.34 PM.jpg53.1 KB · Views: 4

SNAG-2022-12-22 2.09.34 PM.jpg53.1 KB · Views: 4 -

SNAG-2022-12-22 2.15.38 PM.jpg58.3 KB · Views: 4

SNAG-2022-12-22 2.15.38 PM.jpg58.3 KB · Views: 4 -

SNAG-2022-12-22 2.37.23 PM.webp18.4 KB · Views: 6

SNAG-2022-12-22 2.37.23 PM.webp18.4 KB · Views: 6