Tmate

Well-Known Member

How can you match the hole spacing of blind holes when you can't use a transfer punch? You could use dial calipers and do a bunch of math to determine the spacing or you could do this:

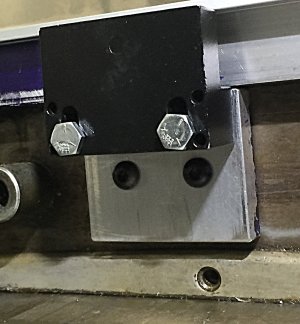

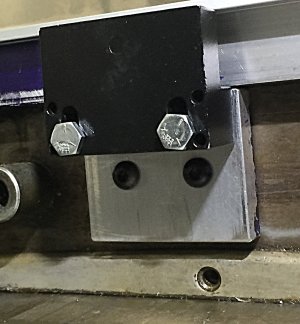

In this case, I needed to fabricate a bracket to mount a magnetic scale reader head for a DRO to the back of the saddle on my mill. The saddle had existing 1/4" x 20 threaded holes, and I wanted to use those rather than drill and tap new holes.

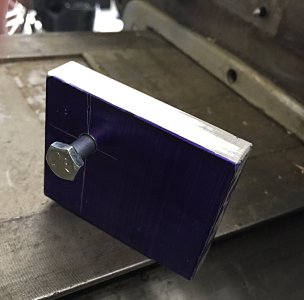

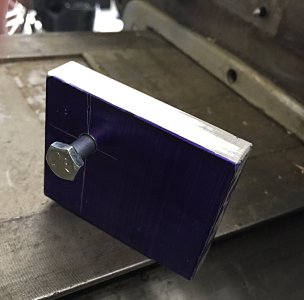

In the first photo, I knew that the holes were aligned vertically, but didn't know the distance between them. I needed to space the holes in the bracket to bolt up to the mill.

I first determined the location of the first hole and drilled it. I then machined a short stub of drill rod that would slide snugly into one of the existing threaded holes, but not so tightly that it couldn't be easily pulled out. I turned a point onto the stub that sticks out of the hole 3/16" or so.

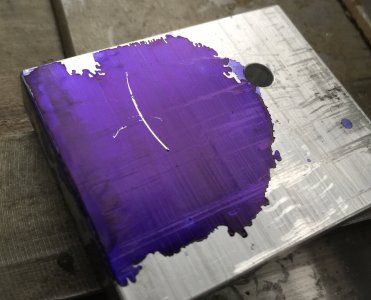

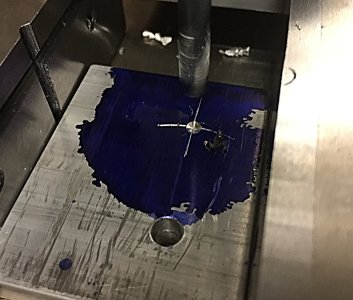

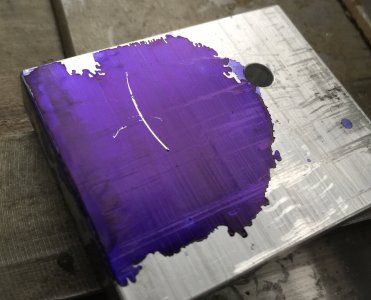

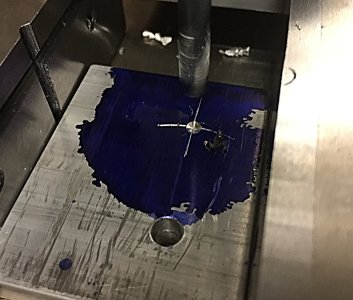

I applied Dykem Blue to one side of the bracket being fabricated, and then bolted it loosely to the mill using the hole already drilled. I then scribed an arc onto the back of the bracket using the pointed stub. I scribed a line across the arc the same distance from the top as the first hole. That gave me the exact location of the second hole, which I center drilled and then drilled.

In this case, I needed to fabricate a bracket to mount a magnetic scale reader head for a DRO to the back of the saddle on my mill. The saddle had existing 1/4" x 20 threaded holes, and I wanted to use those rather than drill and tap new holes.

In the first photo, I knew that the holes were aligned vertically, but didn't know the distance between them. I needed to space the holes in the bracket to bolt up to the mill.

I first determined the location of the first hole and drilled it. I then machined a short stub of drill rod that would slide snugly into one of the existing threaded holes, but not so tightly that it couldn't be easily pulled out. I turned a point onto the stub that sticks out of the hole 3/16" or so.

I applied Dykem Blue to one side of the bracket being fabricated, and then bolted it loosely to the mill using the hole already drilled. I then scribed an arc onto the back of the bracket using the pointed stub. I scribed a line across the arc the same distance from the top as the first hole. That gave me the exact location of the second hole, which I center drilled and then drilled.