1018Machine

Well-Known Member

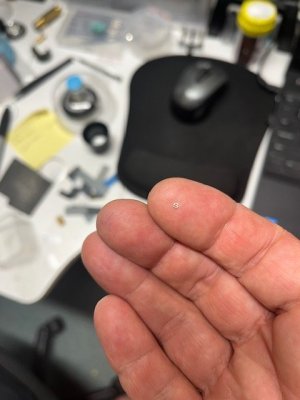

Rounding the bend on my personal watch build and had to find a way to finish silver indices for the dial. They are so small you can barely hold them. Saw a comment elsewhere about laser welding it gave me an idea how to work hold these for finishing!