This will be long. If it seems long to you, it was a friggin marathon for me. Probably the most difficult thing I've made and now its done! yippy! I'll do this in several posts, more tomorrow.

A decade ago I bought an Aciera F1. Before the deal was concluded I managed detect that the spindle was in serious trouble. No runout, but you could move it several though by applying lateral pressure. At the time I had no idea what the bearing arrangement was, or I probably would have passed. Instead I negotiated a deep discount for the pooched bearings and the machine came home with me.

The bearings at the business end are needle bearings with the shaft being the inner race and the housing being the outer race. Deckel used this on some mills as well. What it accomplishes is a very robust spindle with a relative small diameter. It is also in my opinion, the poorest spindle design of all time ..... bearings are a wear part with a service life and with this structure, instead of just replace a bearing, the whole spindle is basically toast.

What to do. There is a place in Germany that wil`l rebuild it. Thousands of dollars. They regrind the surfaces and make or buy needles of the precise sized needed for the new dimensions. Yuck.

Instead I started designing and found with some creative use of threads and mixing in some imperials bearings with super precision AC's, I could just make a spindle that would accommodate the required OD and collet. With a limited range, the challenge is have all the steps you need along shaft and spindle and still having enough room to fit a bearing.

Forlorn and spindless.....

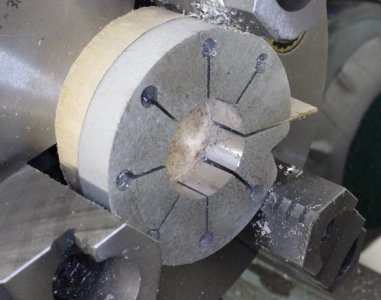

Rouging out the spindle housing

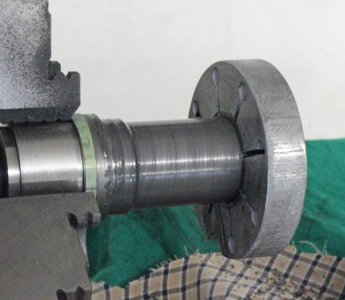

I used preharded 4140 for everything. After roughing, I ground it

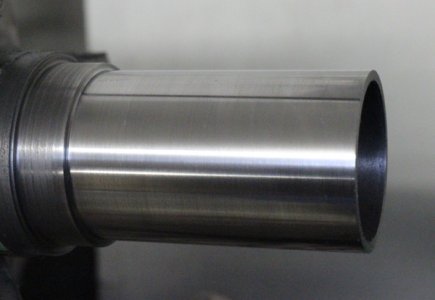

Then some long drilling

more to come....

A decade ago I bought an Aciera F1. Before the deal was concluded I managed detect that the spindle was in serious trouble. No runout, but you could move it several though by applying lateral pressure. At the time I had no idea what the bearing arrangement was, or I probably would have passed. Instead I negotiated a deep discount for the pooched bearings and the machine came home with me.

The bearings at the business end are needle bearings with the shaft being the inner race and the housing being the outer race. Deckel used this on some mills as well. What it accomplishes is a very robust spindle with a relative small diameter. It is also in my opinion, the poorest spindle design of all time ..... bearings are a wear part with a service life and with this structure, instead of just replace a bearing, the whole spindle is basically toast.

What to do. There is a place in Germany that wil`l rebuild it. Thousands of dollars. They regrind the surfaces and make or buy needles of the precise sized needed for the new dimensions. Yuck.

Instead I started designing and found with some creative use of threads and mixing in some imperials bearings with super precision AC's, I could just make a spindle that would accommodate the required OD and collet. With a limited range, the challenge is have all the steps you need along shaft and spindle and still having enough room to fit a bearing.

Forlorn and spindless.....

Rouging out the spindle housing

I used preharded 4140 for everything. After roughing, I ground it

Then some long drilling

more to come....