EricB

Active Member

Hey guys,

I haven't been here in forever! My stupid phone is a piece of junk and I had to get rid of Tapatalk. Anyways, I'm finally getting my lathe back together after a year apart (I know, it's embarassing) and I'm wondering:

What do you guys use for lubrication?

Where do you go for oils/grease?

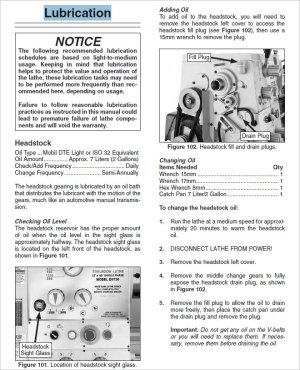

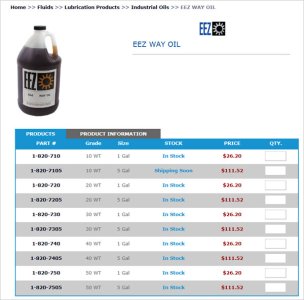

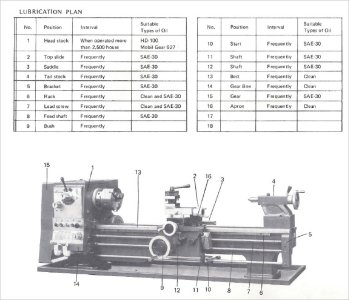

I'm a journeyman machinist, and I know what we use at work and where we get it, but I can't exactly afford (or make use of) huge quantities of high-end synthetic lubes. My lathe originally was supposed to use two types of Texaco oils and a Texaco grease. I've been looking at Mobil. I'd love to hear some suggestions!

I haven't been here in forever! My stupid phone is a piece of junk and I had to get rid of Tapatalk. Anyways, I'm finally getting my lathe back together after a year apart (I know, it's embarassing) and I'm wondering:

What do you guys use for lubrication?

Where do you go for oils/grease?

I'm a journeyman machinist, and I know what we use at work and where we get it, but I can't exactly afford (or make use of) huge quantities of high-end synthetic lubes. My lathe originally was supposed to use two types of Texaco oils and a Texaco grease. I've been looking at Mobil. I'd love to hear some suggestions!