-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Looking for metal worker near Nanaimo

- Thread starter Keiran_dj

- Start date

140mower

Don

NanaimoThird question, nearby to where?

Arbour?Depending on the tooth spacing it may be difficult to hold the sprocket in a lathe chuck.

140mower

Don

Agreed..... If it comes to making an arbour and setting up a tool post grinder, you are definitely getting out of the case of beer price range..... ie, roughly the price of the sprocket....Truthfully, buy a new sprocket , easier and cheaper in the long run by far.

Yeh, but I'd just press a button on my mag chuck controller and make a few passes with the surface grinder, badda bing, badda boom.Agreed..... If it comes to making an arbour and setting up a tool post grinder, you are definitely getting out of the case of beer price range..... ie, roughly the price of the sprocket....

Yeh, but I'd just press a button on my mag chuck controller and make a few passes with the surface grinder, badda bing, badda boom.

A surface grinder was my first thought too. Easy peasy to a few tenths. One beer would more than cover it.

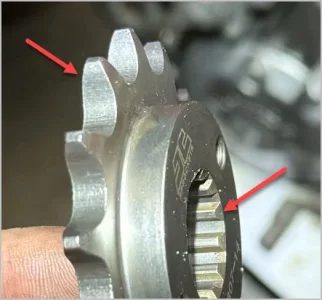

Wondering if anyone is nearby with a lathe and could shave it down a hair and bevel the edge.

If you run out of options nearby, and are willing to cover postage here and back, I'm sure we can fix you up.

Something to be aware either way depending on how much removal & where.

If reducing the sprocket side, I'm pretty certain the tooth section is a defined, size-specific curve meant to operate within a specific roller chain size. Cutting/grinding off a flat on one side will yield a different 'non-optimal' shape.

If reducing the hub side, the splines have a lead in chamfer (easy to do on a lathe but more difficult to mount in a chuck without a fixture). Also now the holes will be shallower.

If reducing the sprocket side, I'm pretty certain the tooth section is a defined, size-specific curve meant to operate within a specific roller chain size. Cutting/grinding off a flat on one side will yield a different 'non-optimal' shape.

If reducing the hub side, the splines have a lead in chamfer (easy to do on a lathe but more difficult to mount in a chuck without a fixture). Also now the holes will be shallower.

Attachments

140mower

Don

Still have to possibly work around that shoulder and then chamfer the edges of each tooth. Then the next question becomes, fully hardened or case hardened, if only case, then you are definitely better off getting a new one...... If not hard, the same steps need to be taken as to champhers etc.Yeh, but I'd just press a button on my mag chuck controller and make a few passes with the surface grinder, badda bing, badda boom.

This comes from my only experience with grinders being, die, angle and bench, so I am sure that I am missing something that makes life easier than I see it......

Maybe I misread the first post. I thought he just needed 1mm taken off the hub. I don't see how that affects the tooth profile.

Now if he wants 1mm taken off the tooth profile, then that is a whole nuther kettle of fish! If so, then I'm on the page of just buying a new gear.

Now if he wants 1mm taken off the tooth profile, then that is a whole nuther kettle of fish! If so, then I'm on the page of just buying a new gear.

140mower

Don

You might be right...... But in typical homeshop fashion, how could we possibly make it easy?Maybe I misread the first post. I thought he just needed 1mm taken off the hub. I don't see how that affects the tooth profile.

Now if he wants 1mm taken off the tooth profile, then that is a whole nuther kettle of fish! If so, then I'm on the page of just buying a new gear.

FatherWes

Wes

I think the OP has moved on. He hasn’t provided clarification to any questions.

And; I have an XR650L. I’ve never heard of a front sprocket that was too wide. The OEM sprockets are notoriously too narrow and they wobble, eventually ruining the splines on the output shaft, which means a full tear down to replace the shaft. It’s a fairly common (short term) “fix” to weld the new sprocket on…

There are sprockets available (KKBike SuperPinion) that offer a much wider contact and improve the method of securing the sprocket.

kkbike.it

kkbike.it

I see there’s a Chinese copy of the SuperPinion available now too.

And; I have an XR650L. I’ve never heard of a front sprocket that was too wide. The OEM sprockets are notoriously too narrow and they wobble, eventually ruining the splines on the output shaft, which means a full tear down to replace the shaft. It’s a fairly common (short term) “fix” to weld the new sprocket on…

There are sprockets available (KKBike SuperPinion) that offer a much wider contact and improve the method of securing the sprocket.

Pinion for Honda - step 15/520 - Superpinion 147/15T

Superpinion is the innovative pinion for your Honda, patented, made in Italy - Honda FMX 650, FX 650, NX Dominator 650, SLR 650, Vigor 650, XR-L 650, XR-R 600

I see there’s a Chinese copy of the SuperPinion available now too.