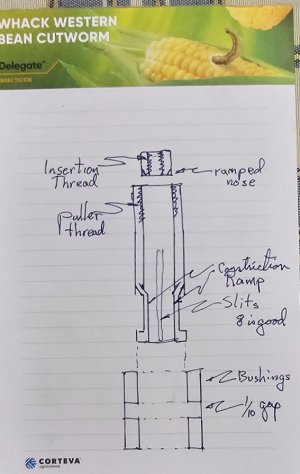

So a job that comes up often is the need to remove 2 small flanged bushings. They are installed in a lug from opposite directions so there is not much room to work. There is only a small gap about .100" where the bushing ends meet. The standard method is to get in there with a pin punch usually in an air hammer and knock out the first bearing then removal of the second is easy by pulling it through from the opposite direction. The second method is to drill the head off one bushing then drive the remains of the first bushing and the second one out together. Both of these methods are high risk to the casting the lug is mounted on. This part is probably worth north of $100k so getting rough with it is not a good idea. There is a repair to the bore for minor damage but this has it's own issues with custom bushings with special plating being required. Expensive and too long of a time frame to acquire.

Does anyone have any ideas for something that would make this safer and easier. I have had zero luck with the slide hammer type of remover they just slip off. The bushings are put in with epoxy primer. Protects the bore but makes them harder to remove.

Does anyone have any ideas for something that would make this safer and easier. I have had zero luck with the slide hammer type of remover they just slip off. The bushings are put in with epoxy primer. Protects the bore but makes them harder to remove.